What is Metal fabrication?

Metal fabrication is the process of manipulating and shaping metal materials to create a desired product or component. It involves various techniques such as cutting, bending, welding, and assembling metal parts to form structures or objects.

Metal fabrication can be used to manufacture a wide range of products, including machinery, equipment, structural components, and decorative items. The process typically involves skilled workers, specialized tools, and machinery to transform raw metal materials into finished products according to specific design specifications.

Table of Contents

Metal fabrication stats

Based on the information provided from the internet sources, here are some statistics related to Metal fabrication:

1. Global Fabricated Metal Market:

According to a report by ResearchAndMarkets.com, the global fabricated metal market was valued at $21.4 billion in 2021 and is projected to reach $34.1 billion by 2031, growing at a CAGR of 4.8% from 2022 to 2031. The market is driven by technological developments, growing R&D activities, and the implementation of automation and advanced production technologies. Steel, aluminum, gold, tin, silver, and copper are some of the metal types used in Metal fabrication processes. CAD software, automation, and machinery solutions are widely used technologies in the Metal fabrication industry.

2. Metal fabrication Equipment Market:

The size of the Metal fabrication Equipment market was USD 74.1 billion in the current year and is expected to register a CAGR of over 4.5% during the forecast period. The Asia-Pacific (APAC) region dominates the Metal fabrication equipment market in terms of demand, driven by developing economies like India, China, and Indonesia, as well as industrialized countries like Japan and South Korea. Europe, particularly countries like Germany, France, and Italy, is the second-largest market for Metal fabrication equipment.

The automotive industry and manufacturing companies are the major consumers of fabrication equipment.

The demand for fabrication equipment is expected to increase due to the growing population, rapid industrialization, and increasing energy demand. However, the high price of raw materials may pose a challenge to market expansion.

3. Apparent Steel Consumption:

The steel market has faced challenges due to factors such as war-related disruptions, poor demand outlook, and rising energy prices. Apparent steel consumption saw a significant decline in the third quarter of 2022, totaling 32.2 million tonnes, the lowest level since the post-pandemic peak period. In 2022, apparent steel consumption experienced its third annual recession in the last four years, with a decrease of 4.6%.

The consumption is predicted to decrease further in 2023, albeit at a lower rate of 1.9%. However, in 2024, with favorable developments in the industrial outlook and improvements in steel demand, the apparent steel consumption is expected to recover modestly by 1.6%.

The future evolution of energy prices and the impact of the Russia-Ukraine war on global supply chains will play a significant role in these developments.

Please note that these statistics are sourced from the provided internet information, and specific details and data may vary based on different sources and reports.

Types of Metal fabrication techniques:

There are several common Metal fabrication techniques used to shape and manipulate metal materials. Here are some of the key techniques:

1. Cutting:

Cutting is the process of separating metal into desired shapes and sizes. It can be achieved through various methods such as sawing, shearing, laser cutting, plasma cutting, or waterjet cutting.

2. Bending:

Bending is used to create curved or angular shapes in metal. It involves applying force to the metal to deform it along a specific axis. Common bending methods include press brake bending, roll bending, and tube bending.

3. Welding:

Welding is the process of joining two or more metal pieces together. It involves melting the metal surfaces and adding a filler material, which cools and solidifies to form a strong bond. Different welding techniques include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, arc welding, and spot welding.

4. Machining:

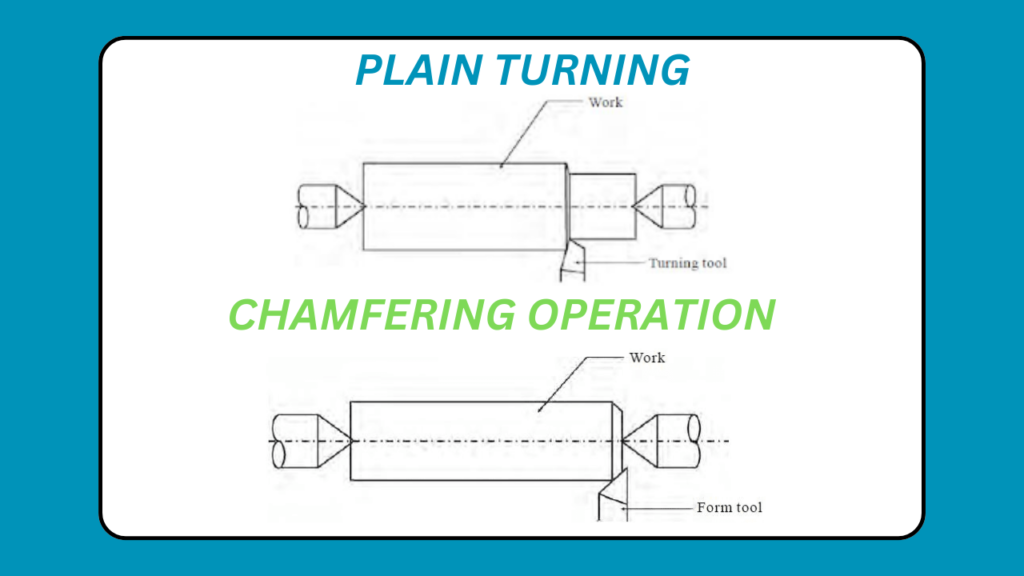

Machining is the process of removing material from a metal workpiece using cutting tools to achieve the desired shape or surface finish. It includes operations like milling, turning, drilling, and grinding.

5. Forming:

Forming techniques involve reshaping metal without removing any material. Examples include roll forming, where metal is passed through a series of rollers to shape it, and deep drawing, which is used to create hollow parts by drawing a flat metal sheet into a die.

6. Assembly:

Assembly involves joining different metal components together to create a finished product. This can be done through methods such as riveting, bolting, or using adhesives.

7. Finishing:

Finishing processes are used to enhance the appearance and protect the surface of the metal. Common finishing techniques include polishing, buffing, painting, powder coating, and electroplating.

Types of modern Metal fabrication techniques:

In addition to traditional Metal fabrication techniques, there are several modern techniques that have emerged with advancements in technology. Here are a few notable modern techniques in Metal fabrication:

1. 3D Printing/Additive Manufacturing:

3D printing, also known as additive manufacturing, is a revolutionary technique that builds objects layer by layer using a computer-controlled process. Metal 3D printing allows for the creation of complex and intricate designs with high precision, reducing the need for traditional fabrication methods such as cutting and welding.

2. CNC Machining:

Computer Numerical Control (CNC) machining utilizes computer-controlled machines to precisely shape and machine metal components. It offers high accuracy and repeatability, making it suitable for complex and intricate designs. CNC machines can perform various operations such as milling, turning, and drilling with minimal human intervention.

3. Laser Cutting:

Laser cutting has become increasingly popular in Metal fabrication. It uses a high-powered laser beam to cut through metal with precision and speed. Laser cutting offers clean cuts, minimal material waste, and the ability to work with a wide range of metals and thicknesses.

4. Waterjet Cutting:

Waterjet cutting utilizes a high-pressure jet of water mixed with an abrasive substance to cut through metal. It is a versatile technique that can handle various materials and thicknesses, providing precise cuts without heat-affected zones or mechanical stress.

5. Robotic Automation:

Robotic automation is being employed in Metal fabrication processes to enhance efficiency and productivity. Robots can perform tasks such as welding, material handling, and assembly with speed and accuracy, reducing human labor and increasing consistency.

6. Hybrid Processes:

Hybrid processes combine multiple techniques to achieve efficient and precise Metal fabrication. For example, hybrid laser-arc welding combines laser welding and arc welding to improve productivity and weld quality.

7. Digital Simulation and Modeling:

Advanced software tools and computer simulations are used to model and simulate Metal fabrication processes. This enables virtual testing and optimization of designs, reducing the need for physical prototypes and minimizing errors in fabrication.

These modern techniques have transformed the Metal fabrication industry, allowing for greater design freedom, increased efficiency, and improved quality in the production of metal components and products.

Technologies used for Metal fabrication :

Metal manufacturing techniques utilize various technologies to shape, manipulate, and assemble metal materials. Here are some of the key technologies commonly used in metal manufacturing:

1. Computer-Aided Design (CAD):

CAD software is used to create detailed digital models of metal components or products. It allows for precise design specifications, dimensional accuracy, and the ability to simulate and optimize designs before fabrication.

2. Computer-Aided Manufacturing (CAM):

CAM software translates CAD designs into instructions for machines and equipment. It generates toolpaths, specifies cutting parameters, and determines the sequence of operations for machining or fabrication processes.

3. Numerical Control (NC) and Computer Numerical Control (CNC):

NC and CNC technologies use computerized systems to control machines and equipment. They enable precise control of cutting tools, movements, and positioning, resulting in accurate and repeatable fabrication processes.

4. Robotics and Automation:

Industrial robots are utilized in metal manufacturing for tasks such as welding, material handling, and assembly. Automation technologies streamline processes, increase efficiency, and enhance precision, reducing human labor and improving productivity.

5. Laser Technology:

Laser technology is widely used in metal manufacturing processes. Laser cutting and welding techniques offer high precision, fast processing speeds, and the ability to work with a wide range of metal materials and thicknesses. Laser marking and engraving are also utilized for product identification and customization.

6. Additive Manufacturing (3D Printing):

Additive manufacturing, or 3D printing, utilizes computer-controlled machines to build metal components layer by layer. Technologies such as selective laser melting (SLM) and electron beam melting (EBM) enable the production of complex and customized metal parts with reduced material waste.

7. Advanced Materials and Alloys:

The development and use of advanced materials and alloys have expanded the capabilities of metal manufacturing. For example, high-strength steels, titanium alloys, and aluminum alloys offer enhanced properties such as lightweighting, increased durability, and improved performance in various applications.

8. Simulation and Modeling:

Simulation and modeling software tools are employed to analyze and optimize metal manufacturing processes. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations help in predicting and improving the performance, strength, and integrity of metal components.

These technologies, along with continuous advancements in automation, data analytics, and artificial intelligence, contribute to the ongoing evolution and optimization of metal manufacturing processes, enabling greater efficiency, precision, and customization.

How does Custom Metal fabrication work

Custom Metal fabrication involves the process of creating unique metal components or products based on specific customer requirements or design specifications. Here’s a general overview of how custom Metal fabrication works:

1. Initial Consultation:

The process begins with an initial consultation between the customer and the Metal fabrication provider. During this phase, the customer discusses their specific needs, design requirements, desired functionality, and any special considerations.

2. Design and Engineering:

Based on the customer’s requirements, the Metal fabrication provider’s design and engineering team creates detailed drawings or computer-aided design (CAD) models of the custom metal component or product. These designs consider factors such as dimensions, materials, tolerances, and manufacturing feasibility.

3. Material Selection:

The appropriate metal material is chosen based on the specific requirements of the project, including factors such as strength, durability, corrosion resistance, and aesthetics. Common metal materials used in custom fabrication include steel, aluminum, stainless steel, brass, and copper.

4. Material Preparation:

Once the design is finalized, the selected metal material is prepared for fabrication. This may involve cutting the metal sheet, bar, or tube into the required dimensions using techniques such as shearing, sawing, laser cutting, or waterjet cutting.

5. Metal Forming and Shaping:

The metal material is shaped and formed according to the design specifications. This can include processes like bending, rolling, stamping, or deep drawing to achieve the desired shape and geometry of the component.

6. Welding and Joining:

If the design requires the assembly of multiple metal pieces, welding or joining techniques are employed. Welding processes such as MIG welding, TIG welding, or spot welding are used to fuse the metal parts together, ensuring strong and durable connections.

7. Machining and Finishing:

Additional machining operations may be performed to refine the component’s shape or achieve specific features. This can involve processes like milling, drilling, or grinding. After machining, the custom metal component undergoes finishing treatments such as polishing, deburring, sandblasting, painting, powder coating, or electroplating to enhance its appearance and provide protection against corrosion.

8. Quality Control and Inspection:

Throughout the fabrication process, quality control measures are implemented to ensure that the final product meets the required standards. Inspection techniques such as dimensional checks, visual inspection, and non-destructive testing may be performed to verify the component’s accuracy, structural integrity, and surface quality.

9. Delivery and Installation:

Once the custom metal component or product is complete and passes the quality control checks, it is packaged and delivered to the customer. If necessary, the fabrication provider may also offer installation services to ensure proper integration of the metal component into the customer’s application.

Why you should outsource Metal fabrication ?

There are several reasons why one might choose to outsource Metal fabrication rather than performing it in-house. Here are some of the advantages of outsourcing Metal fabrication:

1. Expertise and Specialization:

Metal fabrication companies specialize in their field and have extensive knowledge and experience in working with various metals, techniques, and equipment. By outsourcing, you gain access to their expertise and benefit from their specialized skills, ensuring high-quality fabrication and efficient processes.

2. Cost Savings:

Setting up an in-house Metal fabrication facility can be a significant investment. By outsourcing, you can avoid the expenses associated with purchasing equipment, maintaining a facility, hiring and training specialized staff, and managing ongoing operations. Outsourcing allows you to benefit from economies of scale, as the fabrication provider can spread costs across multiple projects and customers.

3. Time Efficiency:

Metal fabrication projects often require significant time and resources. Outsourcing allows you to focus on your core business activities, while the fabrication provider takes care of the fabrication process. They have the necessary equipment, technology, and manpower to complete projects efficiently and meet tight deadlines.

4. Access to Advanced Equipment and Technology:

Metal fabrication companies frequently invest in advanced equipment and technology to enhance their capabilities. By outsourcing, you gain access to their state-of-the-art machinery, which may be cost-prohibitive for your own facility. This can result in improved precision, speed, and quality of fabrication.

5. Scalability and Flexibility:

Outsourcing Metal fabrication gives you the flexibility to scale your production based on demand. Whether you need small prototype runs or large-scale production, a fabrication provider can adjust their resources accordingly. This flexibility allows for faster turnaround times and adaptability to changing market conditions.

6. Quality Assurance:

Metal fabrication companies have robust quality control measures in place to ensure the final product meets or exceeds industry standards. They employ skilled inspectors, perform rigorous testing, and adhere to quality management systems. Outsourcing to a reputable fabrication provider gives you confidence in the quality and reliability of the fabricated components.

7. Access to Value-Added Services:

Many Metal fabrication providers offer value-added services such as design assistance, engineering support, material sourcing, finishing options, and even assembly or integration services. These additional services can streamline your supply chain and reduce the complexity of managing multiple vendors.

It’s important to note that the decision to outsource Metal fabrication should be based on factors such as cost analysis, available resources, project requirements, and the overall business strategy. Evaluating the pros and cons of outsourcing versus in-house fabrication will help determine the best approach for your specific needs.

Future of Metal fabrication

The future of Metal fabrication holds several exciting developments driven by advancements in technology, evolving industry trends, and changing market demands. Here are some key aspects that are likely to shape the future of Metal fabrication:

1. Automation and Robotics:

Automation will continue to play a significant role in Metal fabrication, with increased adoption of robotics and advanced automation technologies. Robotic systems will handle repetitive tasks, enhance precision, and improve production efficiency. Collaborative robots (cobots) will work alongside human operators, contributing to safer and more productive work environments.

2. Additive Manufacturing (3D Printing):

Additive manufacturing, also known as 3D printing, will further transform the Metal fabrication landscape. Advancements in metal 3D printing techniques, such as selective laser melting (SLM) and electron beam melting (EBM), will enable the production of complex and customized metal parts with improved speed, accuracy, and cost-effectiveness. Metal 3D printing will find applications in aerospace, automotive, healthcare, and other industries.

3. Digitalization and Connectivity:

The integration of digital technologies and connectivity will enable smarter and more efficient Metal fabrication processes. The Industrial Internet of Things (IIoT) will connect machines, sensors, and devices to collect and analyze real-time data, leading to predictive maintenance, optimized production schedules, and improved overall equipment effectiveness (OEE). Digital twin technology will enable virtual simulations and modeling to optimize designs and improve process efficiency.

4. Advanced Materials and Alloys:

The development and utilization of advanced materials and alloys will continue to expand the capabilities of Metal fabrication. Lightweight and high-strength materials, such as composites and advanced alloys, will find increasing applications in industries like aerospace and automotive, driving the need for advanced fabrication techniques to process these materials effectively.

5. Sustainable Practices:

The Metal fabrication industry will place greater emphasis on sustainability and eco-friendly practices. Energy-efficient manufacturing processes, recycling and waste reduction initiatives, and the use of environmentally friendly coatings and materials will become more prevalent. This focus on sustainability aligns with global efforts to reduce carbon emissions and promote a circular economy.

6. Artificial Intelligence (AI) and Data Analytics:

AI and data analytics will enhance decision-making processes in Metal fabrication. AI algorithms will optimize production parameters, detect defects, and predict equipment failures. Data analytics will enable better process monitoring, quality control, and supply chain management, leading to improved efficiency and cost savings.

7. Human-Machine Collaboration:

While automation and robotics will play a prominent role, human expertise will remain crucial in Metal fabrication. Human operators will focus on higher-level tasks that require creativity, problem-solving, and complex decision-making. The collaboration between humans and machines will be essential for achieving optimal results in terms of productivity, quality, and innovation.

These trends indicate a future in Metal fabrication that is characterized by advanced technologies, increased efficiency, customization, and sustainability. Embracing these advancements will empower the industry to meet the evolving demands of various sectors and contribute to overall industrial progress.

Check out more informative content on home page