Table of content

What is the Micrometer least count?

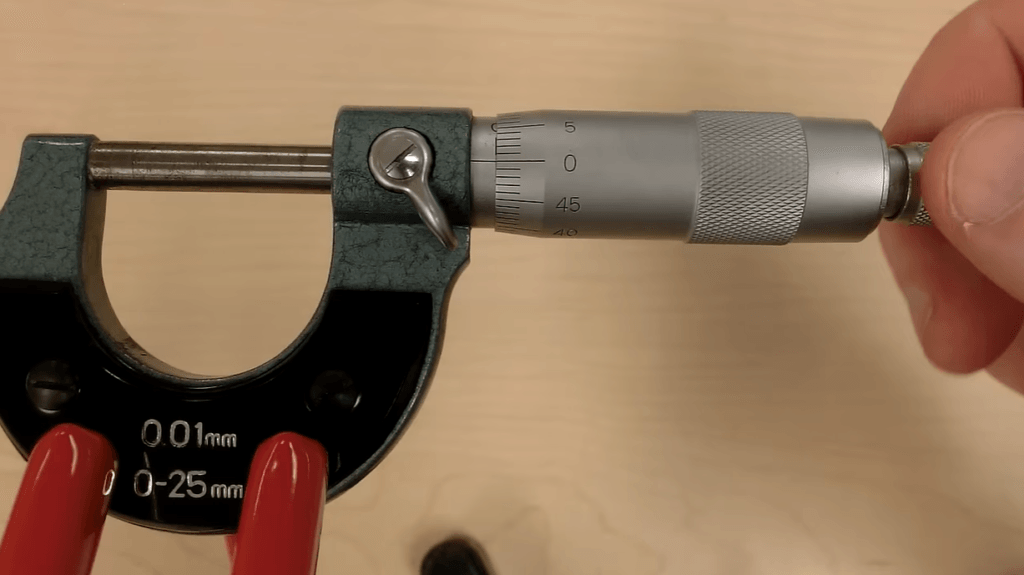

The micrometer least count is 0.01 mm, but the micrometer least count may vary depending on the specific type and model of the micrometer being used. Some micrometers, especially electronic ones, may have a finer least count, such as 0.001mm, So lets understand each type carefully with their particular least count

Also read: Best Vernier Caliper beginners guide 2025

Standard Parts of micrometer:

- Frame: The frame holds the anvil and barrel in constant relation to each other. It’s typically a C-shaped body.

- Anvil: This is the fixed part against which the object being measured is placed.

- Spindle or Barrel: It moves towards the anvil when the thimble is rotated.

- Thimble: The thimble is rotated to move the spindle, and it often contains the ratchet stop for precise control of the applied pressure.

- Sleeve: The sleeve houses the barrel and spindle assembly.

- Screw(Ratchet): The screw provides the fine adjustment needed for accurate measurements.

also read: what are the types of micrometers

How to read a micrometer 0.01 mm

Formula to calculate micrometer least count:

To calculate the micrometer Least count, you can use the formula:

LC = PITCH / NUMBER OF CIRCULAR DIVISIONS

- LC = Least count

- Pitch = It is the distance moved by the screw per revolution (typically the smallest division on the main scale).

- Number of circular divisions = The number of divisions on the circular scale

For example:- if the pitch of the micrometer screw gauge is 1 mm and there are 100 circular divisions, the least count would be

Least count = 1/100 =0.01 mm

How to measure micrometer least count as a beginner

A simple beginner’s guide to finding the least count of a micrometer screw gauge with step-by-step instructions and examples

Step 1: Understand the Parts

Before starting, identify the main parts:

Frame – holds the anvil and barrel

Anvil – fixed measuring face

Spindle – movable measuring face

Sleeve (Main Scale) – has the main scale in mm

Thimble (Circular Scale) – has 50 or 100 divisions

Ratchet Stop – ensures uniform pressure

Step 2: Determine the Pitch of the Screw

Rotate the thimble one full rotation and note how much the spindle moves forward.

Usually, in a standard metric micrometer, one rotation moves the spindle by 0.5 mm.

Hence, Pitch = 0.5 mm.

Step 3: Count the Number of Divisions on the Circular Scale

Check how many divisions are marked on the thimble (circular scale).

Typically, there are 50 divisions.

Step 4: Calculate the Least Count

Calculate Least Count (LC) = P / N.

Example: 0.5 ÷ 50 = 0.01 mm (or 0.5 ÷ 100 = 0.005 mm).

Step 5: Verify the Reading

To verify, close the micrometer gently and ensure the zero of the thimble coincides with the reference line on the sleeve.

Supply:

- Calibration rod or reference standard, clean soft cloth, dust blower or small cleaning brush

Tools:

- Micrometer screw gauge, magnifying lens, small ruler or scale, vernier caliper for verification

Materials: Thin metal wire or sheet for practice, optionally a block gauge for precise calibration.

Precautions to take when measuring or calculating the least count of a micrometer

- Clean the micrometer – Ensure the spindle, anvil, and thimble are free from dust, oil, or dirt before starting.

- Check the zero error – Close the spindle gently on the anvil and confirm if the zero on the thimble coincides with the reference line on the sleeve. If not, note the zero error.

- Avoid excessive force – Always use the ratchet/ friction stop when rotating the spindle. Over-tightening can damage the micrometer and give false readings.

- Ensure proper alignment – Place the object or reference surface squarely between the anvil and spindle, not at an angle.

- Read the scales carefully – While counting sleeve divisions and thimble divisions, keep your eye straight in line with the scale to avoid parallax error.

- Stable environment – Perform measurements in a stable environment; avoid vibrations, and ensure there are no sudden temperature changes, as thermal expansion can affect accuracy.

- Use standard reference – When verifying least count, use a known gauge block or calibrated standard for accuracy.

- Handle with care – Do not drop the micrometer or expose it to shocks, as it may disturb the calibration.

List of Various Micrometer least counts

| Micrometer Type | Least Count |

| Outside Micrometer | 0.01 mm to 0.001 mm |

| Inside Micrometer | 0.01 mm |

| Depth Micrometer | Around 0.01 mm |

| Digital Micrometer | 0.001 mm |

| Blade Micrometer | 0.01 mm |

| Screw Thread Micrometer | 0.01 mm |

| Point Micrometer | 0.01 mm |

| Vernier Micrometer | 0.02 mm |

| Universal/Multi-Anvil Micrometer | Around 0.01 mm |

| Analog Micrometer | Typically 0.01 mm |

What is the Definition of least count ?

The least count refers to the smallest value that can be measured accurately by a measuring instrument. It represents the precision of the instrument, indicating the smallest incremental measurement it can detect or display.

ALSO READ UNDERSTAND THE CONCEPT OF VERNIER CALIPER LEAST COUNT

For example, if a ruler has divisions of millimeters, its least count would be 1 millimeter, as it can measure down to the nearest millimeter. In another instance, if a micrometer has divisions of 0.01 millimeters, then micrometer’s least count would be 0.01 millimeters, allowing for more precise measurements

Frequently asked Questions

What is the Micrometer least count

The micrometer least count is 0.01 mm for standard mechanical micrometers. In advanced digital micrometers, the least count can be as fine as 0.001 mm, providing higher accuracy in measurements.

How to find the least count of micrometer

The least count of a micrometer is found by dividing the pitch of the screw by the number of divisions on the thimble scale. (LC = PITCH / NUMBER OF CIRCULAR DIVISIONS )

How to use micrometer least count formula

How to use it:

Find the pitch: Rotate the thimble one full turn and measure how much the spindle moves (usually 0.5 mm for most micrometers).

Count thimble divisions: Most micrometers have 50 or 100 divisions.

Apply the formula:

For example,

If pitch = 0.5 mm and thimble has 50 divisions,

Least Count = 0.5 mm / 50 = 0.01 mm

This means the micrometer can measure as small as 0.01 mm

When and where do we use a micrometer ? (Applications)

Micrometers are employed wherever precise dimensional measurements are required, ensuring accuracy in various fields ranging from manufacturing to research and development.

- Manufacturing Industry: Micrometers are extensively used in manufacturing for precise measurements of components’ dimensions.

- Engineering: They play a vital role in engineering applications, including mechanical, electrical, and civil engineering, for accurate measurements during design, production, and quality control processes.

- Science Laboratories: Micrometers are commonly found in science labs for measuring small objects with precision, such as the diameter of wires, thickness of materials, and other dimensional parameters.

- Metalworking and Machining: In metalworking and machining industries, micrometers are indispensable for measuring the dimensions of machined parts to ensure they meet precise specifications.

- Automotive Industry: Micrometers are utilized in the automotive sector for measuring engine parts, shafts, bearings, and other critical components to ensure accuracy and reliability.

- Aerospace and Defense: In aerospace and defense industries, micrometers are essential for measuring precision components used in aircraft, missiles, and other aerospace systems