In the world of mechanical engineering and machinery,, understanding what is coupling is crucial because, coupling plays a crucial role in connecting two rotating shafts to transmit power effectively. Whether in industrial machines, automotive systems, or manufacturing equipment, couplings ensure smooth and efficient operations by absorbing misalignment, reducing shock loads, and protecting components from damage. This detailed blog post will explore what coupling is, its types, functions, advantages, and common applications.

Introduction: Understanding the Importance of Coupling

Every mechanical system with rotating parts requires a means to transfer motion and torque from one shaft to another. This is where coupling comes in. Without proper coupling, machines can suffer from misalignment, vibration, excessive wear, and premature failure. For industries aiming to optimize performance and extend machinery lifespan, selecting the right coupling is essential.

In this article, we will cover everything you need to know about coupling, including its purpose, types, selection criteria, and benefits.

Table of Contents

What is Coupling?

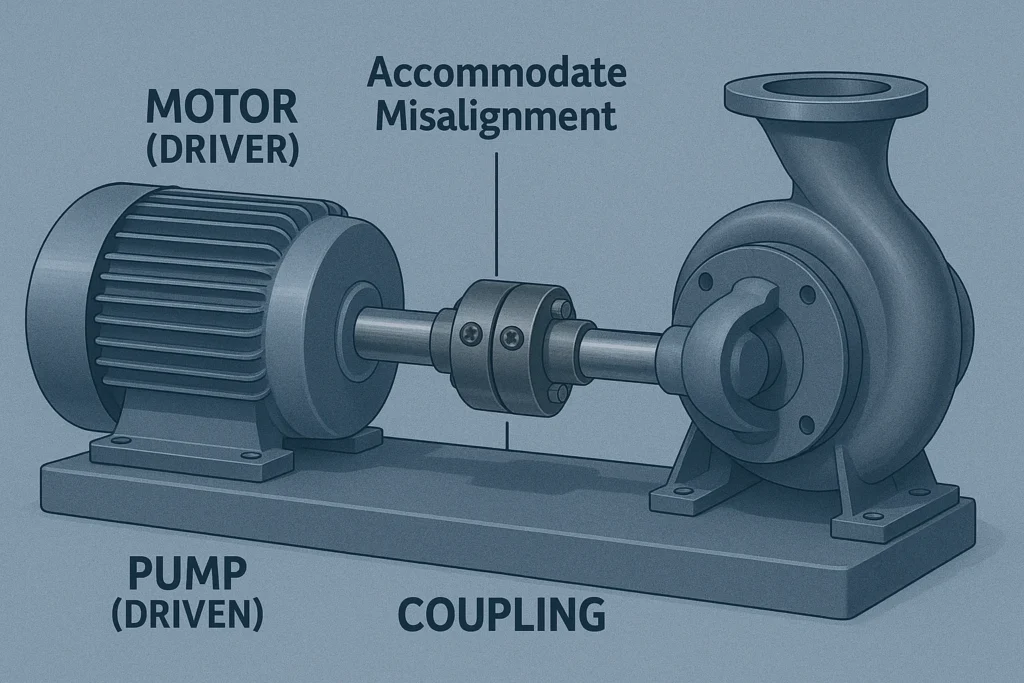

Coupling is a mechanical device used to connect two shafts together at their ends to transmit power. It allows for some degree of misalignment, accommodates movement, and reduces the effects of vibration and shock. In simple terms, coupling joins two pieces of rotating equipment to function as a single unit.

Functions of Coupling

Couplings are not just simple connectors — they perform several critical functions that ensure smooth machinery operation and system longevity. Here’s a detailed look at their key functions:

1. Transmit Power Efficiently

The primary role of a coupling is to transfer torque and rotational motion from one shaft to another, ensuring consistent mechanical power transmission across connected components.

2. Accommodate Misalignment

No system is perfectly aligned at all times. Couplings help adjust for:

- Angular misalignment: Slight angular difference between the shafts.

- Parallel misalignment: Slight offset between the shaft centers.

- Axial misalignment: Slight axial movement due to thermal expansion or contraction.

By compensating for these, couplings prevent excessive wear and reduce stress on bearings and shafts.

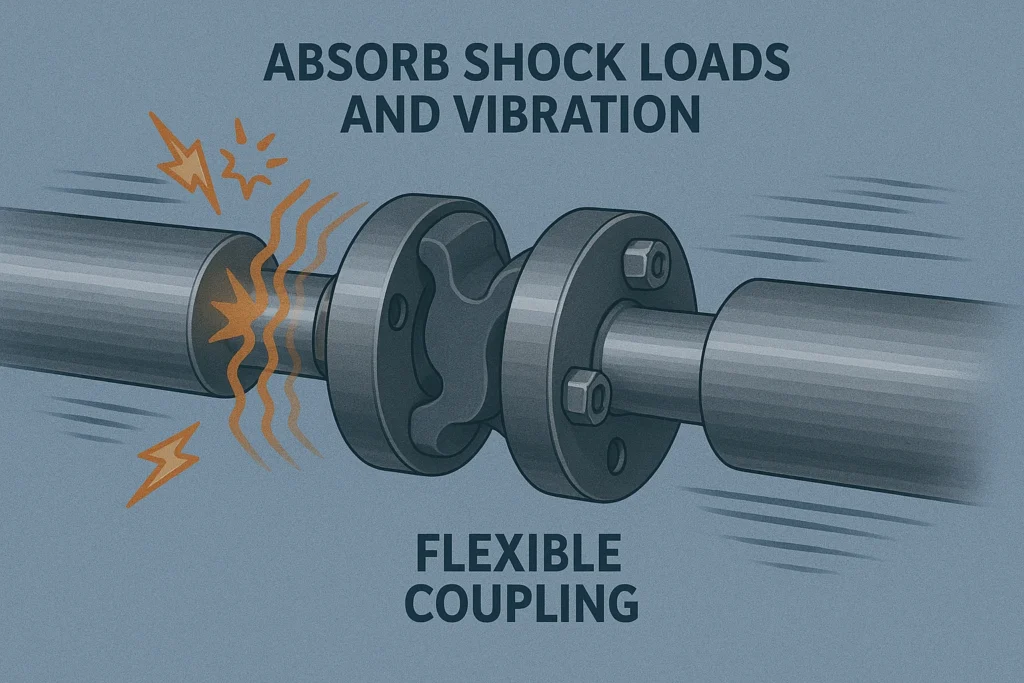

3. Absorb Shock Loads and Vibration

Machines often experience load fluctuations or sudden impacts. Couplings act as a buffer by absorbing these shocks, preventing damage to sensitive components and ensuring stable performance.

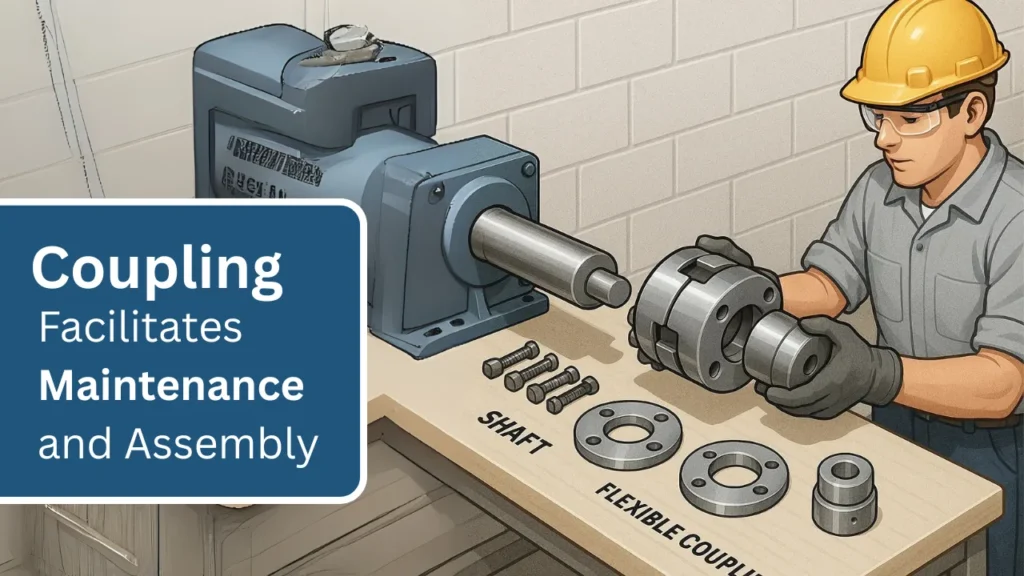

4. Facilitate Maintenance and Assembly

Couplings allow machines to be easily assembled and disassembled without disturbing adjacent components, making maintenance, inspections, and part replacements simpler and faster.

5. Compensate for Wear and Thermal Expansion

Over time, machinery components may shift due to wear or changes in temperature. Couplings can adjust for minor shifts, maintaining proper alignment and performance.

6. Provide Overload Protection

Some couplings are designed to slip or break under excessive load, protecting the system from catastrophic failure.

Summary of Functions:

- Power transmission

- Misalignment accommodation

- Shock absorption

- Easy maintenance

- Wear compensation

- Overload protection

These combined functions make couplings indispensable in industrial and mechanical applications

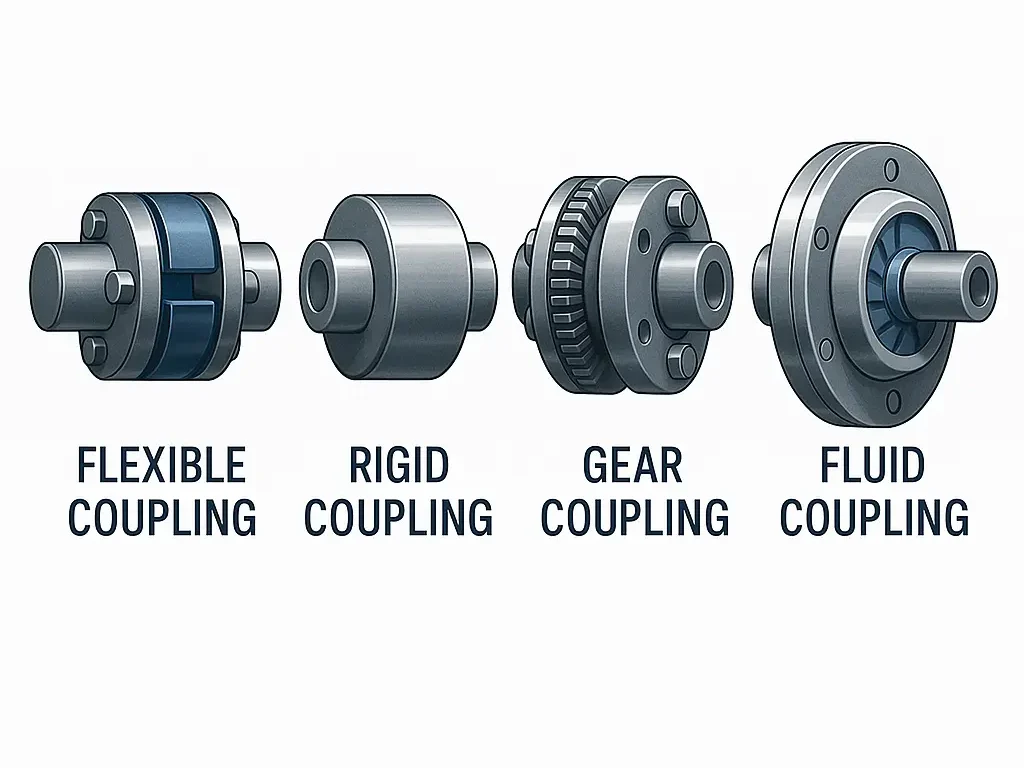

Main Types of Coupling

There are many types of couplings, each designed for specific applications and needs. Broadly, they can be divided into two main categories:

1. Rigid Couplings

Rigid couplings provide a solid connection between shafts and do not allow any relative movement. They are used where precise shaft alignment is required.

Common types of rigid couplings:

- Sleeve or muff coupling

- Clamp or split-muff coupling

- Flange coupling

2. Flexible Couplings

Flexible couplings can accommodate slight misalignments and are ideal for systems where some flexibility is needed.

Common types of flexible couplings:

- Bushed pin-type coupling

- Oldham coupling

- Universal coupling (Hooke’s joint)

- Gear coupling

- Chain coupling

Detailed Overview of Popular Coupling Types

Sleeve or Muff Coupling

- Simple and economical

- Used for transmitting moderate torque

- Consists of a hollow cylinder (sleeve) over the shaft ends

Flange Coupling

- High torque capacity

- Two flanges bolted together

- Common in heavy-duty industrial applications

Bushed Pin-Type Coupling

- Uses rubber or leather bushes for flexibility

- Reduces shock and vibration

Universal Coupling (Hooke’s Joint)

- Transmits torque between shafts at an angle

- Common in automotive drive shafts

Gear Coupling

- High torque transmission capability

- Suitable for high-speed applications

Advantages of Using Coupling

- Increased Equipment Lifespan: Reduces wear on shafts and bearings.

- Improved Efficiency: Ensures smooth power transmission.

- Cost Savings: Minimizes maintenance and downtime.

- Flexibility: Allows for system adjustments without complete disassembly.

- Safety: Absorbs shock loads and prevents machinery damage.

Applications of Coupling in Industry

Couplings are used across various industries, including:

- Manufacturing: Conveyor belts, compressors, mixers

- Automotive: Drive shafts, steering systems

- Energy: Wind turbines, hydroelectric plants

- Marine: Propeller shafts

- HVAC Systems: Fans, pumps, blowers

How to Select the Right Coupling

When choosing a coupling, consider the following factors:

- Amount of torque to be transmitted

- Shaft sizes and alignment

- Operating speed

- Load type (steady, variable, shock)

- Space limitations

- Maintenance requirements

- Environmental conditions (temperature, moisture, chemicals)

Proper selection ensures optimal performance and extends the life of your machinery.

Frequently Asked Questions (FAQs)

Q1: What is the primary purpose of coupling?

A: The main purpose is to transmit power between two shafts while accommodating slight misalignments and reducing shock.

Q2: What is the difference between rigid and flexible coupling?

A: Rigid coupling requires perfect alignment, while flexible coupling allows for some misalignment and absorbs vibration.

Q3: Where is gear coupling used?

A: Gear couplings are used in high-torque, high-speed applications such as heavy industrial machines and rolling mills.

Q4: Can couplings fail?

A: Yes, due to factors like excessive load, misalignment, wear, or improper installation. Regular inspection is essential.

Q5: How often should couplings be maintained?

A: Maintenance frequency depends on the application but typically includes regular inspection, lubrication, and alignment checks.

what is coupling in mechanical engineering

Coupling in mechanical engineering is a device used to connect two rotating shafts to transmit power and accommodate misalignment or movement.

List of Top Coupling Manufacturing Companies in the World

For industries looking for high-quality and reliable couplings, choosing a reputable manufacturer is key. Here’s a list of some of the top coupling manufacturing companies known for their innovation, quality, and global reach:

1. Rexnord Corporation (USA)

A leading global provider of couplings, gear drives, and industrial components, Rexnord offers a wide range of flexible and rigid couplings designed for heavy-duty applications.

2. SKF Group (Sweden)

Known for its expertise in bearings, seals, and lubrication, SKF also manufactures high-performance couplings for diverse industrial uses, including marine and energy sectors.

3. Altra Industrial Motion (USA)

Altra brands like TB Wood’s, Ameridrives, and Bibby offer top-tier couplings, clutches, and brakes, making them a trusted name in power transmission solutions.

4. Siemens AG (Germany)

Siemens produces couplings for energy, mining, and industrial automation sectors, delivering precision-engineered solutions for demanding environments.

5. Lovejoy Inc. (USA)

A division of Timken, Lovejoy is globally recognized for its flexible couplings, jaw couplings, and grid couplings, known for durability and high-performance.

6. Voith GmbH (Germany)

Voith provides hydrodynamic couplings and variable-speed drives, primarily used in mining, cement, and paper industries, emphasizing energy efficiency and system protection.

7. Fenner Drives (UK)

Part of the Michelin Group, Fenner Drives specializes in polymer-based power transmission products, including a variety of flexible couplings and tensioners.

8. Regal Rexnord (USA)

With a portfolio of brands including Kop-Flex and Jaure, Regal Rexnord offers highly engineered couplings for wind, marine, and heavy machinery industries.

9. Tsubaki (Japan)

Renowned for chain and power transmission products, Tsubaki also manufactures precision couplings used in automation, robotics, and conveying systems.

10. Baldor Electric (USA)

A member of the ABB Group, Baldor provides couplings, motors, and drives, serving industrial markets across the Americas and beyond.

These companies are leaders in the global market, offering reliable coupling solutions that meet diverse application requirements

Conclusion, after reading this article you must have under, what is coupling, what is coupling specifically in mechanical engineering, what are the roles or Functions of a coupling is, Coupling applications, importance, types and more,

[top_button]

If you understand it, do share it with your friends and colleagues so that they too can get clarity on what is coupling and its key concepts