Single Point Cutting Tool is one of the most fundamental tools used in machining and manufacturing to achieve high precision. Whether you’re shaping metal on a lathe or learning mechanical engineering, understanding this tool is crucial.

Introduction

In this comprehensive guide, you’ll discover SPCT, Its types, angles, geometry, applications, and materials. advantages

Table of Contents

What is a Single Point Cutting Tool?

A single point cutting tool is a cutting instrument with a single cutting edge used to remove material from a workpiece in machining operations. It’s primarily used in lathe machines, shapers, and slotters.

Simple Definition:

A tool with one cutting edge that removes material from a rotating or stationary workpiece is called a single point cutting tool.

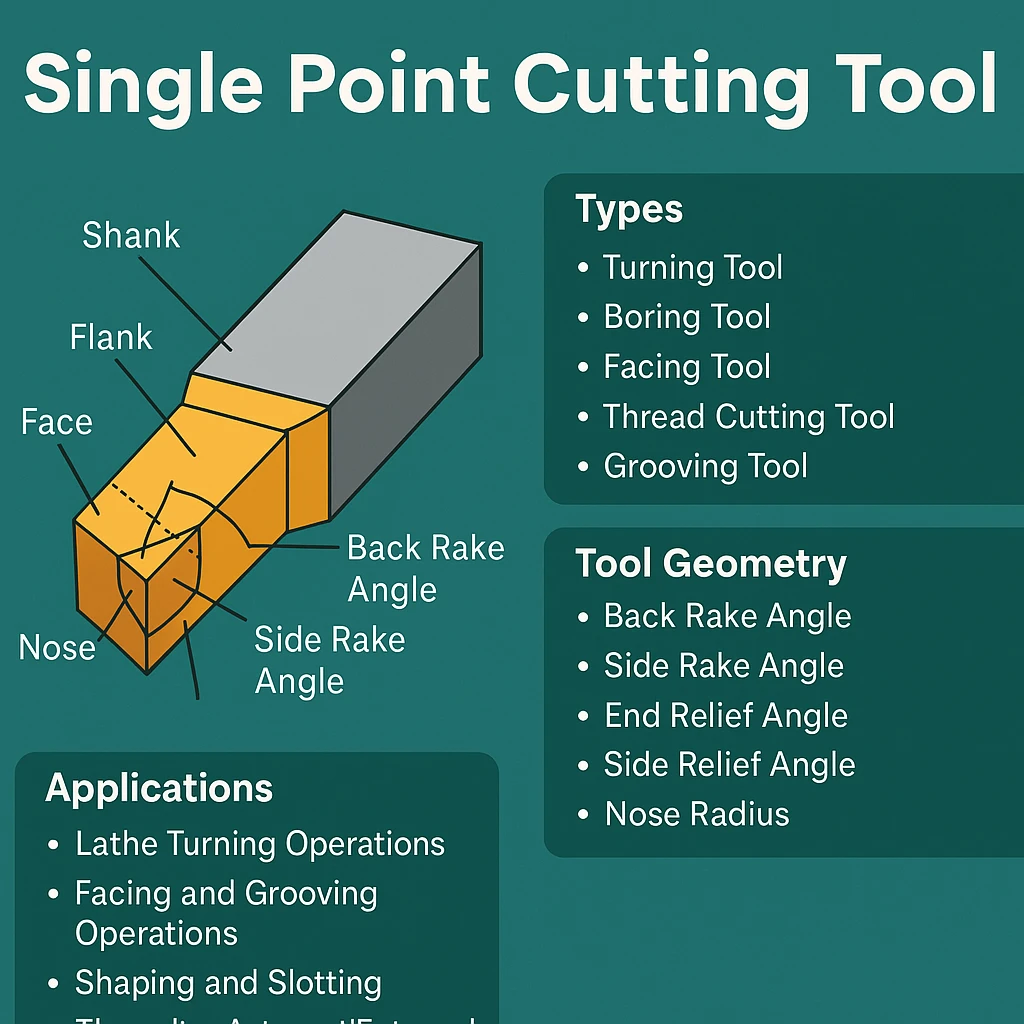

Tool Geometry and nomencleture

Understanding the tool geometry is crucial for performance and surface finish. The geometry includes various angles and parts, which are:

Main Parts:

- Shank – The body of the tool held in the tool post

- Flank – The surface below the cutting edge

- Face – The surface on which chips flow

- Cutting Edge – The part that actually removes material

- Nose – The junction of side and end cutting edges

Types of Cutting with a Single Point Cutting Tool can be obtained

1. Orthogonal Cutting

In orthogonal cutting, the cutting edge of the tool is perpendicular (90°) to the direction of tool travel. This method simplifies the analysis of cutting forces and chip formation.

Characteristics:

- Cutting edge is straight and set at a right angle to the workpiece.

- Produces a continuous chip with minimal deformation.

- Used mainly for academic or theoretical study due to its simplicity.

Applications:

- Ideal for machining processes involving soft materials.

- Common in laboratory demonstrations and research.

2. Oblique Cutting

In oblique cutting, the cutting edge of the tool is inclined at an acute angle (not 90°) to the direction of tool travel. This is the most common cutting method in practical machining.

Characteristics:

- Cutting edge is set at an angle less than 90° to the feed direction.

- Produces a helical or spiral-shaped chip.

- Cutting force is distributed more evenly, increasing tool life.

Applications:

- Used in real-world operations such as turning, facing, and shaping.

- Preferred in industrial settings for better surface finish and tool durability.

Summary Table

| Type of Cutting | Cutting Edge Angle | Chip Formation | Application Area |

|---|---|---|---|

| Orthogonal Cutting | 90° | Flat, continuous chip | Theoretical studies |

| Oblique Cutting | < 90° | Helical or curled chip | Industrial machining |

Types of Single Point Cutting Tools

1. Turning Tool

Used for reducing the diameter of cylindrical workpieces on a lathe.

2. Boring Tool

Used for enlarging or finishing the inside diameter of a hole.

3. Facing Tool

Used for cutting a flat surface perpendicular to the axis of the workpiece.

4. Thread Cutting Tool

Used to cut internal or external threads on cylindrical surfaces.

5. Grooving Tool

Used to make grooves or recesses in workpieces.

Tool Angles in a Single Point Cutting Tool

The tool angles determine chip flow, tool life, and machining efficiency. These are standardized as per ASA (American Standards Association) and ORS (Orthogonal Rake System)

Important Tool Angles:

- Back Rake Angle – Influences chip flow direction

- Side Rake Angle – Affects chip thickness and flow

- End Relief Angle – Prevents rubbing against the job

- Side Relief Angle – Prevents side cutting edge from rubbing

- Nose Radius – Enhances surface finish

- Cutting Edge Angle – Affects the depth of cut and strength

Characteristics of a Single Point Cutting Tool

- Only one main cutting edge does the cutting

- Commonly used in turning, shaping, and planing

- Made from tool steel, HSS, or carbide

- Can be re-sharpened and reused

- Typically mounted on lathes or other machine tools

Materials Used in Single Point Cutting Tools

Tool material impacts cutting performance, durability, and cost.

| Material Type | Description & Use |

|---|---|

| High-Speed Steel (HSS) | Affordable, easy to grind, used in general cutting |

| Carbide | Excellent for high-speed machining |

| Ceramics | Good for high-speed operations, brittle in nature |

| CBN (Cubic Boron Nitride) | Suitable for hard materials |

| Diamond | Used for ultra-precise and fine finish cuts |

Applications

Single point cutting tools are widely used in:

- Lathe turning operations

- Facing and grooving operations

- Shaping and slotting

- Threading internal/external parts

- Machining hard or soft metals

🔧 Used in industries like automotive, aerospace, die-making, and general manufacturing.

Advantages

- Simple and easy to manufacture

- Easy to regrind and reuse

- Cost-effective for small batch production

- Suitable for both roughing and finishing

- Compatible with various machine tools

Difference Between Single and Multi Point Cutting Tools

| Feature | Single Point Tool | Multi Point Tool |

|---|---|---|

| Cutting Edges | One | More than one |

| Examples | Lathe tools, shaping tools | Drills, milling cutters |

| Applications | Turning, shaping | Drilling, milling, grinding |

| Surface Finish | Better for low-speed cutting | Better for high-speed operations |

| Heat Distribution | Poor | Better due to multiple edges |

FAQs About Single-Point Cutting Tool

1. What is the main function of a single point cutting tool?

Its main function is to remove material from a workpiece using one cutting edge, usually on a lathe.

2. Which machine commonly uses a single-point cutting tool?

Lathe machines most commonly use SPCTs for turning operations.

3. How many cutting edges are in a single-point cutting tool?

As the name suggests, only one cutting edge is active during the cutting process.

4. What is the ideal material for making a single point cutting tool?

High-Speed Steel (HSS) is most commonly used, while carbide is preferred for high-performance machining.

5. What are common single point cutting tool interview questions?

What are the different tool angles?

Explain the geometry of a single point cutting tool.

Difference between rake angle and relief angle?

Conclusion: Why Understanding SPCT Matters

Whether you’re a budding mechanical engineer, a CNC operator, or preparing for a competitive exam, understanding the single point cutting tool gives you a solid foundation in manufacturing processes. Its simplicity, versatility, and effectiveness make it an essential part of modern-day machining.