Introduction

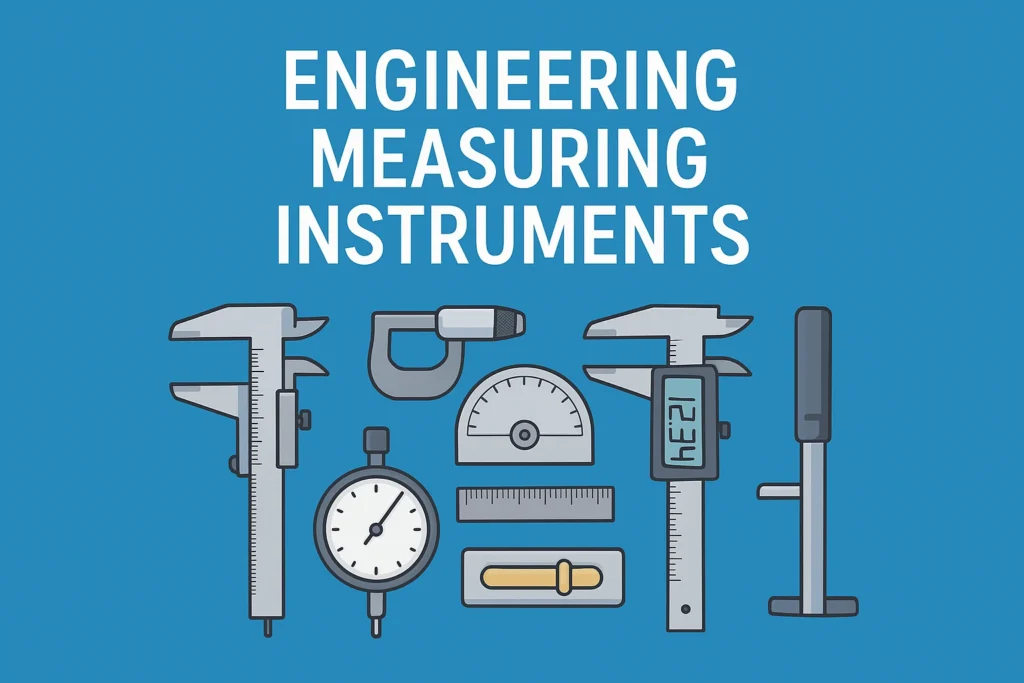

Engineering measuring instruments are essential tools used to measure, monitor, and verify different physical quantities like length, pressure, temperature, speed, and electrical properties in engineering fields. These instruments provide accurate data that engineers rely on for design, quality control, troubleshooting, and research. Without proper measurement tools, manufacturing processes, construction projects, and scientific experiments would lack precision and reliability.

In this article, we will explore the definition of engineering measuring instruments, their working principles, formulas, practical applications, advantages, and limitations. Whether you are a student, professional engineer, or simply curious about industrial tools, this guide will give you a complete understanding of engineering measuring instruments.

List of 40+ Engineering Measuring Instruments in Table format

| Sl. No. | Category | Instrument | Purpose |

|---|---|---|---|

| 1 | Linear Measurement | Vernier Caliper | Measures internal, external dimensions, and depth |

| 2 | Linear Measurement | Outside Micrometer | Measures external diameter/thickness with high precision |

| 3 | Linear Measurement | Inside Micrometer | Measures internal diameters |

| 4 | Linear Measurement | Depth Micrometer | Measures depth of slots, holes, and recesses |

| 5 | Linear Measurement | Steel Rule | Basic tool for length measurement |

| 6 | Linear Measurement | Height Gauge | Measures and marks vertical dimensions |

| 7 | Linear Measurement | Depth Gauge | Measures depth of holes or grooves |

| 8 | Linear Measurement | Digital Caliper | Electronic measurement of length and depth |

| 9 | Angle Measurement | Protractor | Measures basic angles |

| 10 | Angle Measurement | Bevel Protractor | Measures angles precisely |

| 11 | Angle Measurement | Sine Bar | Used with slip gauges for accurate angle measurement |

| 12 | Angle Measurement | Clinometer | Measures slope or tilt angles |

| 13 | Surface & Alignment | Dial Indicator | Checks runout, roundness, and alignment |

| 14 | Surface & Alignment | Test Indicator | Measures small displacement or surface irregularity |

| 15 | Surface & Alignment | Surface Plate | Provides reference flatness for inspection |

| 16 | Surface & Alignment | Feeler Gauge | Measures small gaps and clearances |

| 17 | Surface & Alignment | Straight Edge | Checks flatness and straightness |

| 18 | Precision Standards | Gauge Blocks (Slip Gauges) | Calibration and standard reference |

| 19 | Precision Standards | Ring Gauge | Checks external diameter of shafts |

| 20 | Precision Standards | Plug Gauge | Checks internal diameter of holes |

| 21 | Precision Standards | Snap Gauge | Quick checking of external dimensions |

| 22 | Precision Standards | Thread Gauge | Checks screw thread pitch and form |

| 23 | Workshop Tools | Combination Square | Used for layout marking, angle checking |

| 24 | Workshop Tools | Try Square | Checks squareness |

| 25 | Workshop Tools | Caliper (Divider/Inside/Outside) | Transfers and measures distances |

| 26 | Workshop Tools | Marking Gauge | Scribes lines parallel to edges |

| 27 | Advanced Instruments | CMM (Coordinate Measuring Machine) | 3D dimensional inspection |

| 28 | Advanced Instruments | Profile Projector (Optical Comparator) | Inspects profile shapes and dimensions |

| 29 | Advanced Instruments | Laser Scanner | 3D surface and shape measurement |

| 30 | Advanced Instruments | Bore Gauge | Measures internal diameter of holes |

| 31 | Electrical | Multimeter | Measures voltage, current, resistance |

| 32 | Electrical | Oscilloscope | Analyzes waveforms of electrical signals |

| 33 | Electrical | Wattmeter | Measures electrical power |

| 34 | Electrical | Clamp Meter | Measures current without breaking circuit |

| 35 | Electrical | LCR Meter | Measures inductance, capacitance, resistance |

| 36 | Thermal & Fluid | Thermometer | Measures temperature |

| 37 | Thermal & Fluid | Pyrometer | Measures high temperatures (furnaces, kilns) |

| 38 | Thermal & Fluid | Pressure Gauge | Measures fluid pressure |

| 39 | Thermal & Fluid | Vacuum Gauge | Measures low pressures/vacuum |

| 40 | Thermal & Fluid | Flowmeter | Measures flow rate of fluids |

| 41 | Thermal & Fluid | Anemometer | Measures wind/air velocity |

| 42 | Miscellaneous | Hardness Tester | Measures hardness of materials |

| 43 | Miscellaneous | Tachometer | Measures rotational speed (RPM) |

| 44 | Miscellaneous | Vibration Meter | Measures vibration levels |

| 45 | Miscellaneous | Ultrasonic Thickness Gauge | Measures material thickness using ultrasound |

| 46 | Miscellaneous | Lux Meter | Measures illumination levels |

| 47 | Miscellaneous | Sound Level Meter | Measures noise levels (dB) |

Definition of Engineering Measuring Instruments

Engineering Measuring Instruments are devices designed to determine and quantify physical quantities such as length, force, pressure, temperature, electrical current, and speed with accuracy and precision, usually expressed in standard units (SI system).

Note: Measurement = Numerical Value × Unit

For example: A length measurement of 5 meters → (5 × m).

These instruments convert physical quantities into readable outputs (scale, dial, digital display, or signal).

Detailed Explanation

Working Principle / Concept

Engineering measuring instruments work on different physical principles such as:

- Mechanical deformation (e.g., spring balance for force measurement).

- Optical principles (e.g., vernier calipers using light reflection and magnification).

- Electrical signals (e.g., voltmeter detecting potential difference).

- Thermal expansion (e.g., thermometer measuring temperature rise).

- Electromagnetic induction (e.g., tachometer for speed measurement).

Each type of instrument converts a real-world physical quantity into a measurable output that engineers can record and analyze.

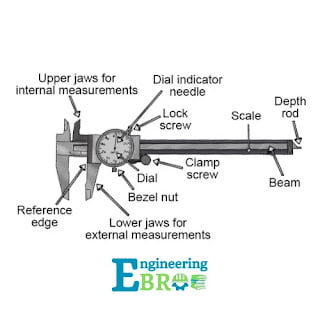

Parts or Components

Most measuring instruments consist of the following general components:

- Sensing Element – Detects the physical quantity (e.g., bimetallic strip in thermometers).

- Transducer/Converter – Converts detected quantity into readable form.

- Scale/Display – Provides output in numeric or graphical format.

- Supporting Frame/Body – Ensures stability and durability.

(Diagram reference: A vernier caliper showing jaws, scale, and sliding mechanism.)

Formula and Step-by-Step Calculation Example

Let’s take an example of Vernier Caliper measurement:

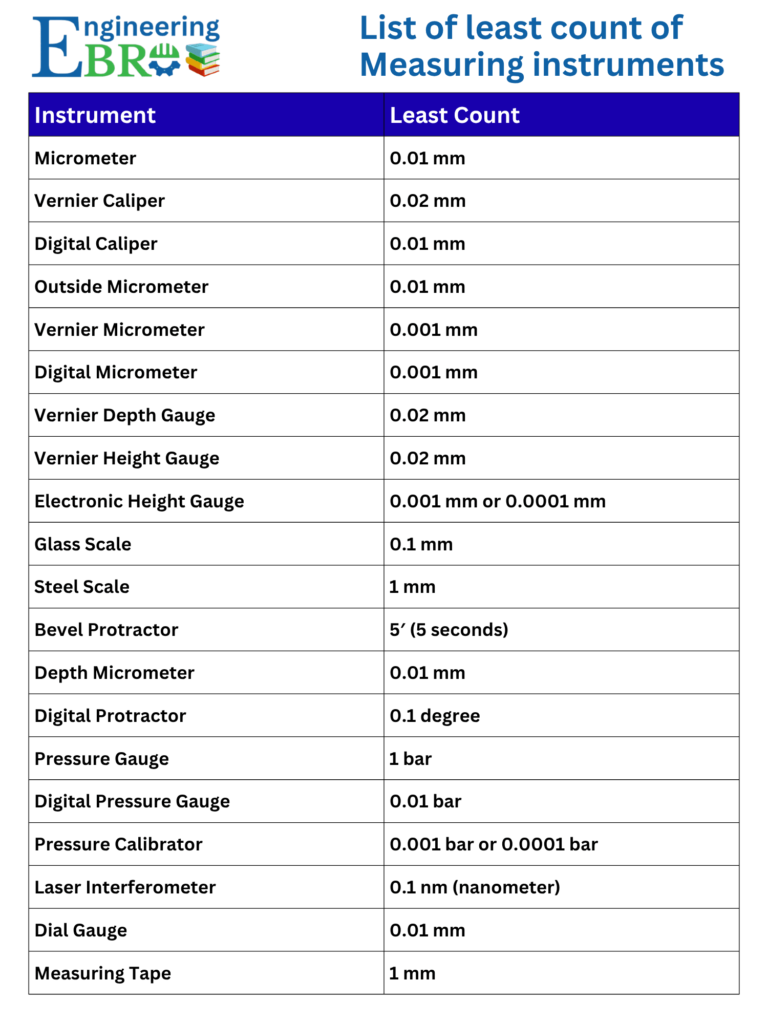

Formula: Reading = Main Scale Reading + (Vernier Scale Division × Least Count)

Step Example:

- Main Scale Reading = 12 mm

- Vernier Scale Division = 4

- Least Count = 0.02 mm

Example: Reading = 12 + (4 × 0.02) = 12.08 mm

Thus, the object length = 12.08 mm.

Practical Usage Example

- A micrometer screw gauge is used to measure the thickness of a thin sheet in mechanical engineering workshops.

- An ammeter is used in electrical engineering labs to measure current in a circuit.

- A tachometer measures the RPM of a motor in mechanical industries.

These instruments ensure accuracy in design, safety in operations, and quality in production.

Applications & Importance

Engineering measuring instruments are used in various industries:

- Mechanical Engineering: Measurement of machine parts, shafts, bolts, and bearings.

- Civil Engineering: Surveying land, measuring distances, angles, and material testing.

- Electrical Engineering: Measuring voltage, current, resistance, and power.

- Automobile Industry: RPM, speed, and fuel measurement.

- Aerospace & Defense: Precision tools for navigation and equipment testing.

- Medical Equipment: Blood pressure monitors, thermometers, ECG machines.

👉 Importance:

- Ensures quality control in production.

- Improves safety and reliability of systems.

- Provides accuracy in research and design.

- Reduces errors and material waste.

Advantages & Limitations

Advantages

- High accuracy and precision.

- Essential for industrial standardization.

- Improves product quality and safety.

- Provides reliable data for research and innovation.

- Wide range of applications across industries.

Limitations

- Require calibration regularly.

- Can be expensive (especially digital/electronic).

- Sensitive to environmental conditions (temperature, vibration, humidity).

- Skilled operators are often required for accurate use.

Comparisons

| Feature | Vernier Caliper | Micrometer | Dial Gauge |

|---|---|---|---|

| Accuracy | ±0.02 mm | ±0.01 mm | ±0.001 mm |

| Range | 0–300 mm | 0–25 mm | 0–50 mm |

| Usage | External & internal measurements | Thickness, diameter | Surface flatness & alignment |

FAQs

Q1. What are engineering measuring instruments?

Engineering measuring instruments are tools used to measure physical quantities such as length, angle, surface finish, pressure, temperature, and electrical parameters in engineering applications.

Q2. Why are measuring instruments important in engineering?

They ensure accuracy, precision, and quality control in manufacturing, design, and testing processes.

Q3. What is the difference between accuracy and precision in measurement?

Accuracy is how close a measurement is to the true value, while precision is how consistently repeated measurements give similar results.

Q4. What is the least count of an instrument?

The least count is the smallest value that an instrument can measure accurately. For example, a Vernier Caliper may have a least count of 0.02 mm.

Q5. Which instruments are used for linear measurement?

Common instruments include Vernier Caliper, Micrometer, Steel Rule, Height Gauge, and Depth Gauge.

Q6. Which instruments are used for angle measurement?

Protractor, Bevel Protractor, Sine Bar, and Clinometer are widely used for angle measurements.

Q7. What is a CMM (Coordinate Measuring Machine)?

A CMM is an advanced measuring instrument used for 3D dimensional inspection of complex parts.

Q8. What are gauge blocks used for?

Gauge blocks (slip gauges) are precision standards used for calibration and reference measurements.

Conclusion

Engineering measuring instruments are the backbone of accuracy in science, technology, and industry. From mechanical workshops to advanced aerospace research, they ensure precision, safety, and efficiency. Understanding their working principles, applications, and limitations helps engineers make better decisions in design and quality control.

Also Read

Lathe Machine: Definition, Parts, and Working……

Micrometer: Uses and Formula……

Reference links for the blog post