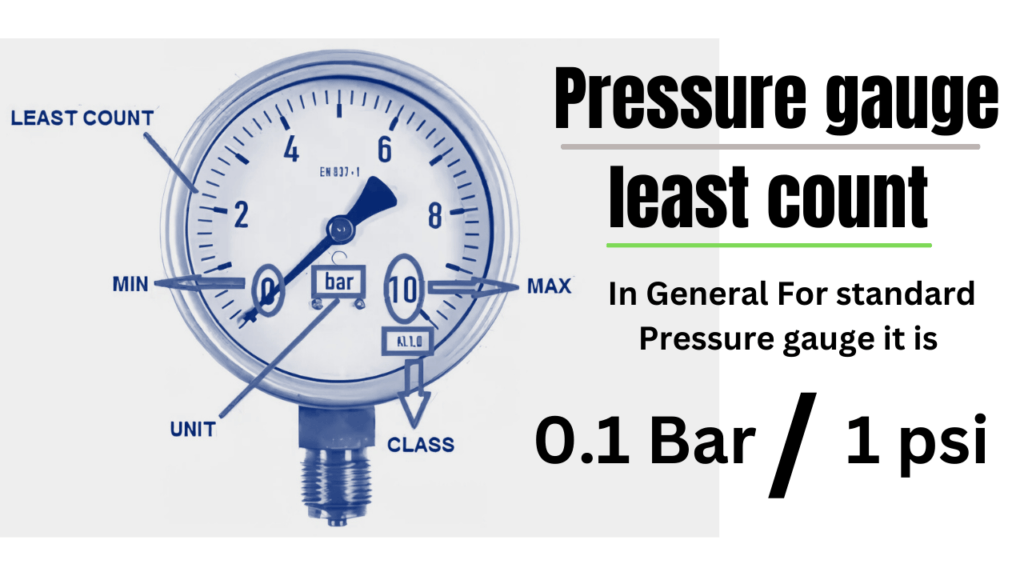

In general, for most standard mechanical pressure gauges used in industrial applications, the pressure gauge least count usually ranges from:

- 0.1 bar (in case of finer scales with 100 divisions over a 10 bar range)

- 1 psi (for gauges with a scale marked in pounds per square inch and a similar range)

Table of Contents

What is a pressure gauge least count?

The least count of a pressure gauge refers to the smallest measurement that the gauge can reliably detect or display. It is the smallest division on the scale of the gauge, representing the precision of the instrument. The least count is an important parameter in determining the accuracy of measurements made with the gauge.

ALSO READ Least count of 15 top measuring instruments list

Best Vernier Caliper beginners guide 2025

How to calculate the Pressure gauge least count,

You can use the formula:

For example:

- If a manometer or dial pressure gauge has a scale with 100 divisions between 0 and 1 bar, the least count would be 1/100 bar, or 0.01 bar.

- For a digital pressure gauge, the least count could be determined by the smallest digit or decimal place shown on the display, such as 0.1 psi or 0.01 bar, depending on the instrument’s design.

Why checking the Pressure gauge least count is important before you start taking reading for a system ?

Checking the pressure gauge’s least count before taking readings is important for several reasons:

- Accuracy: It helps you know how precise the readings can be. A larger least count means less precision.

- Proper Gauge Selection: Ensures you use the right gauge for your system’s pressure range.

- Avoid Misinterpretation: Knowing the least count helps you understand how close or far the reading is from the actual value.

- System Monitoring: A gauge with the right least count detects small pressure changes that may affect system performance.

- Safety & Compliance: Ensures the gauge meets safety standards and provides reliable readings for critical systems.

In short, the least count ensures you get accurate, reliable, and safe pressure readings for your system.