Rapid prototyping is a modern design and development approach used to quickly create functional or visual models of a product. It enables teams to test concepts, gather real-world feedback, and refine ideas before full-scale production. By combining digital tools like CAD modeling, 3D printing, and software simulation, rapidprototyping helps reduce time, cost, and design risks—making it a cornerstone of modern product innovation.

Whether you’re developing a physical product or a digital interface, rapidprototyping allows you to transform ideas into testable solutions quickly and efficiently.

Table of Contents

What is Rapid Prototyping?

Rapid prototyping is the process of creating a quick physical or digital model of a design using computer-aided technologies. These prototypes simulate the functionality, appearance, and usability of the final product, enabling faster validation and iteration.

This process is essential in engineering, product design, software development, and manufacturing. It bridges the gap between concept and production, ensuring that teams can experiment with multiple versions without committing extensive resources.

Why is it Important?

Traditional product development is time-consuming and expensive. Rapidprototyping, on the other hand, accelerates this process by:

- Allowing early user testing and feedback collection

- Reducing errors and rework before manufacturing

- Enabling multiple design iterations in less time

- Supporting cross-functional collaboration among teams

This iterative process ensures that the final design is both user-centered and production-ready.

How Does Rapid Prototyping Work?

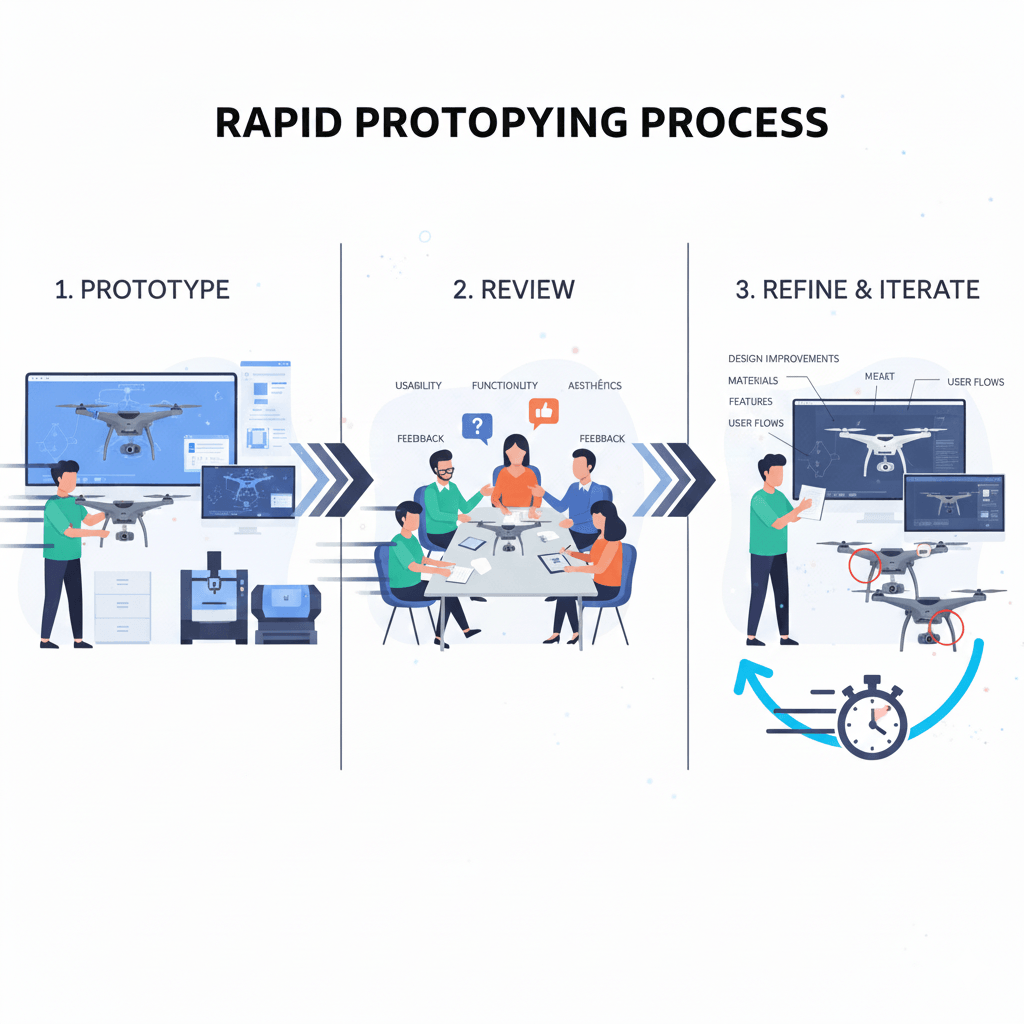

Rapidprototyping typically follows a three-step iterative cycle:

1. Prototype

Create an initial model of the product—either physical (using 3D printing, CNC machining) or digital (using CAD or UX design tools). This prototype helps visualize the concept and test core functionalities.

2. Review

Share the prototype with users and stakeholders. Gather feedback on usability, functionality, and aesthetics to identify gaps and opportunities for improvement.

3. Refine & Iterate

Use the feedback to make design improvements. This stage may involve modifying shapes, materials, features, or user flows until the prototype meets performance and design standards.

This prototype–review–refine loop continues until the final product achieves the desired results.

Rapid prototyping techniques

Rapid prototyping can be categorized into several types based on fidelity, tools, and application area:

1. Low-Fidelity Prototyping

Used in early design stages to explore ideas.

- Sketches: Hand-drawn visuals to represent concepts.

- Paper Models: Simple layouts simulating user flows.

- Wireframes: Digital outlines showing product structure.

2. High-Fidelity Prototyping

Used for detailed testing and validation.

- Digital Mockups: Realistic product visuals created using Figma, Adobe XD, or Sketch.

- Interactive Prototypes: Clickable interfaces for testing user interaction.

3. 3D Prototyping

Used for physical product development.

- 3D Printing: Builds tangible prototypes layer by layer using resin or plastic.

- CNC Machining: Cuts material directly from solid blocks for precise prototypes.

- CAD Models: Detailed designs for mechanical testing and simulation.

4. Software Prototyping

Used for testing digital products and systems.

- Code Prototypes: Lightweight versions built with real code to test performance.

- Simulation Models: Software models replicating system behavior under different conditions.

5. Mixed-Fidelity Prototyping

Combines both low- and high-fidelity prototypes to test multiple aspects simultaneously. This approach balances speed and accuracy, allowing teams to iterate efficiently.

Rapid Prototyping Applications

Rapid prototyping is widely used across industries such as:

- Automotive Engineering: Testing aerodynamics, fit, and ergonomics.

- Aerospace: Creating lightweight, complex components.

- Consumer Electronics: Testing usability and design aesthetics.

- Medical Devices: Designing and validating surgical tools and prosthetics.

- Software & UI/UX Design: Validating digital workflows and user interfaces.

- Architecture: Producing scale models for design visualization.

Benefits

1. Faster Innovation

Designers can quickly explore multiple ideas, helping companies stay ahead in competitive markets.

2. Cost Efficiency

Detecting design flaws early reduces expensive post-production fixes.

3. Enhanced Collaboration

Visual prototypes improve communication between designers, engineers, and clients.

4. User-Centered Design

Continuous testing with real users ensures products meet expectations.

5. Reduced Risk

Early validation reduces uncertainty, improving decision-making and minimizing design errors.

Example:

Imagine a startup called Health Hub developing a fitness app. Instead of coding the full product first, they:

- Build a clickable wireframe using Figma.

- Test it with fitness enthusiasts to gather insights.

- Refine the UI, add new workout tracking features, and improve navigation.

By the time the app launches, it’s already user-tested and optimized—saving months of development time and preventing costly redesigns.

Key Points

- Encourages innovation through experimentation.

- Facilitates early validation and error detection.

- Promotes cross-department collaboration.

- Saves time and resources by reducing rework.

- Enables scalable and flexible product design.

Future

With the integration of AI, IoT, and advanced 3D printing technologies, rapidprototyping is evolving rapidly. Intelligent prototyping tools can now predict design flaws, simulate real-world stress, and auto-optimize materials for performance. As digital twins and additive manufacturing grow, rapidprototyping will remain central to innovation in the Industry 4.0 era.

FAQs

1. What is the main purpose of rapid prototyping?

To quickly test, validate, and improve product designs before mass production.

2. How does rapid prototyping differ from traditional prototyping?

Rapid prototyping emphasizes speed and iteration using modern tools like CAD, 3D printing, and digital simulations.

3. What industries use rapid prototyping most?

Engineering, aerospace, automotive, medical, software, and consumer electronics sectors.

4. What are the main tools for rapid prototyping?

Figma, Adobe XD, AutoCAD, SolidWorks, Fusion 360, and 3D printers.

5. Is rapid prototyping suitable for small businesses?

Yes. Even startups benefit from rapid prototyping, as it lowers risk, speeds up feedback, and minimizes development costs.

Conclusion

Rapid prototyping is revolutionizing how products are designed, tested, and delivered. It empowers teams to innovate faster, validate ideas with real users, and launch more reliable products. Whether through 3D printing, software simulation, or digital design, rapidprototyping is not just a process—it’s a mindset for creating smarter, user-focused solutions in today’s fast-paced world.