1. Introduction

A Star Delta Starter is one of the most commonly used reduced-voltage starting methods for three-phase induction motors. It is designed to minimize the high inrush current that occurs during motor startup by initially connecting the motor in a star configuration and then automatically shifting it to a delta configuration once it reaches approximately 80% of its rated speed.

This technique offers an effective balance between starting torque and current limitation, making it suitable for medium to large induction motors (typically above 5 HP). In industrial and commercial installations, the Star-Delta Starter is preferred for its simplicity, reliability, and cost-effectiveness compared to more advanced electronic soft starters.

Table of Contents

2. What is a Star Delta Starter?

A Star-Delta Starter is an electrical control and protection device used to start three-phase induction motors with reduced starting current. It achieves this by first connecting the motor windings in a star (Y) configuration during the start phase, where each phase receives only 1/√3 (about 58%) of the line voltage.

Once the motor gains sufficient speed, the connection automatically changes to delta (Δ), allowing the motor to run at full line voltage. This transition reduces mechanical stress and prevents voltage dips in the electrical network.

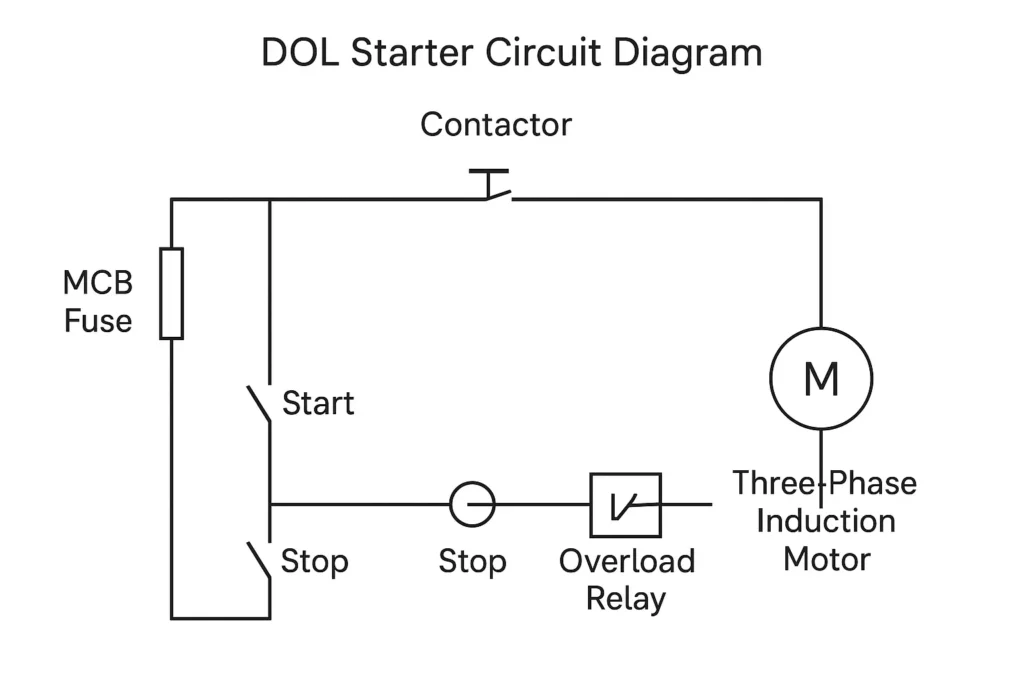

ALSO READ: What is DOL starter. Detailed explanation

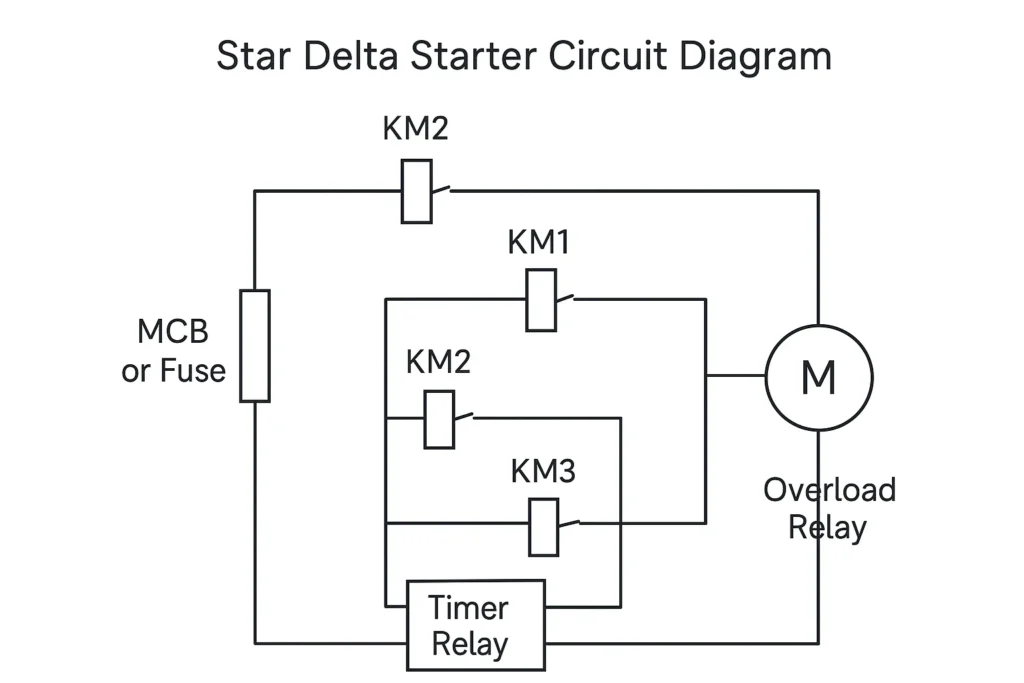

3. Star Delta Starter Circuit Diagram

3.1 Circuit Description

The Star-Delta Starter consists of:

- Power Circuit: Connects the motor terminals to the supply through three contactors and an overload relay.

- Control Circuit: Contains the push buttons, timer relay, and interlocking connections that control the switching sequence.

Working Sequence:

- Start Phase: Motor connected in Star configuration → reduced voltage and current.

- Transition Phase: Timer relay activates → Star contactor opens, Delta contactor prepares.

- Running Phase: Motor connected in Delta configuration → full voltage operation.

4. Working Principle of Star Delta Starter

The working principle of Star Delta Starter is to start the motor at a lower voltage and then switch to full voltage once it reaches near-rated speed.

When Start Button is Pressed

The main contactor and star contactor energize simultaneously.

The motor windings connect in a star configuration, so each phase receives line voltage/√3.

The motor starts with low current (1/3 of DOL current) and low torque (1/3 of DOL torque).

Timer Action:

After a preset time (typically 5–10 seconds), the timer relay de-energizes the star contactor.

After a short delay (mechanical interlock), the delta contactor energizes.

Delta Running Mode:

The motor windings are now connected in a delta configuration.

Each winding receives full line voltage, enabling the motor to deliver full-rated torque and operate at normal speed.

Stopping the Motor:

When the stop button is pressed, the control circuit de-energizes all contactors, disconnecting the motor from the supply.

5. Components of Star Delta Starter

The Star-Delta Starter employs both power and control elements, working together for smooth and safe motor operation.

1. Main Contactor (KM1):

Connects the motor circuit to the three-phase supply line. It remains energized throughout the operation, both in star and delta modes.

2. Star Contactor (KM2):

Connects the ends of the motor windings together to form a star connection during the start phase. It opens during transition to delta.

3. Delta Contactor (KM3):

Connects the motor windings in delta configuration once the star connection is released. It remains energized during the running condition.

4. Timer Relay:

Controls the duration of the star connection and automatically switches the circuit from star to delta after a set time.

5. Overload Relay:

Monitors current levels and protects the motor from overheating or overloading by breaking the control circuit.

6. Start and Stop Push Buttons:

- Start Button (NO): Initiates the motor starting sequence.

- Stop Button (NC): Interrupts the control circuit to stop the motor.

7. MCB or Fuse:

Protects the starter and motor from short circuits and major faults.

6. Star Delta Starter Control Circuit Operation

The control circuit of a Star-Delta Starter uses interlocking and timing control to ensure that the star and delta contactors never close simultaneously, which would cause a short circuit.

Sequence Overview:

- Pressing the Start button energizes the main and star contactors, and the timer starts counting.

- After the preset time, the timer coil opens the star contact and closes the delta contact.

- The motor transitions smoothly from low-voltage start to full-voltage run.

- Pressing the Stop button or tripping the overload relay de-energizes all coils.

Interlocking Methods:

- Electrical Interlocking: Achieved using normally closed (NC) auxiliary contacts to prevent simultaneous energization of star and delta contactors.

- Mechanical Interlocking: Ensures physical prevention of both contactors closing together.

7. Construction and Wiring

A Star-Delta Starter typically includes:

- A control panel housing all contactors, relays, and wiring terminals.

- Clearly marked L1, L2, L3 input terminals and U1, V1, W1 motor terminals.

- Three interconnecting jumpers for the star-delta transition.

- Control wiring that links push buttons, timer relay, and auxiliary contacts for proper sequence control.

During construction, all wiring must follow standard color codes and be tested for insulation resistance before energizing.

8. Advantages of Star Delta Starter

- Reduced Starting Current:

The current drawn is one-third that of the Direct-On-Line method, minimizing voltage dips. - Lower Starting Torque Impact:

Smooth mechanical acceleration prevents stress on shafts and couplings. - Simple and Economical Design:

Uses standard contactors and timers, making it cost-effective compared to electronic soft starters. - Suitable for Large Motors:

Effective for motors ranging from 5 HP to 75 HP. - Automatic Transition:

The built-in timer ensures smooth switching without manual intervention.

9. Disadvantages of Star Delta Starter

- Reduced Starting Torque:

Only one-third of the full-load torque is available during startup, unsuitable for heavy-load starts. - Transition Current Peaks:

During star-to-delta changeover, a sudden current spike may occur due to phase mismatch. - Complex Wiring:

Requires multiple contactors and more wiring than DOL starters. - Fixed Transition Timing:

In traditional models, transition depends solely on timer setting, not on actual motor speed. - Not Suitable for Lightly Loaded Motors:

Sudden transition can cause torque pulsation and mechanical vibration.

10. Applications of Star Delta Starter

The Star-Delta Starter is widely used where motors require reduced voltage starting and smooth acceleration. Common applications include:

- Water pumps and submersible motors

- Industrial air compressors

- Conveyor systems and crushers

- Centrifugal blowers and fans

- Refrigeration and HVAC compressors

- Textile and paper machinery

- Elevators and hoisting equipment

11. How to Make a Star Delta Starter

Building a Star-Delta Starter involves connecting three contactors, a timer relay, and protective devices as per standard wiring practice.

11.1 Steps to Build:

- Mount three contactors (Main, Star, Delta) and a timer relay on a control panel.

- Connect the three-phase supply to the main contactor input.

- Wire the motor terminals to allow both star and delta configurations.

- Integrate the timer relay coil with the control circuit to automate transition.

- Add push buttons, overload relay, and auxiliary contacts for safe control.

- Test the setup under no-load conditions before connecting to an actual motor.

11.2 Safety Tips:

- Always use correct ratings for contactors and relays.

- Ensure the interlocking is correctly wired to avoid short circuits.

- Ground all metallic enclosures.

- Verify timer delay as per motor size and load.

12. Difference Between Star and Delta Connection

| Parameter | Star Connection (Start Mode) | Delta Connection (Run Mode) |

|---|---|---|

| Voltage per Winding | Line Voltage / √3 | Line Voltage |

| Current per Winding | Line Current / √3 | Equal to Line Current |

| Torque Produced | 1/3 of full-load torque | Full-load torque |

| Purpose | To limit starting current | To run at full power |

| Duration | Temporary (during startup) | Continuous (during running) |

13. Star Delta Starter vs DOL Starter

| Feature | Star-Delta Starter | DOL Starter |

|---|---|---|

| Starting Method | Reduced voltage (two-step) | Direct full voltage |

| Starting Current | 2–3 times FLC | 6–8 times FLC |

| Starting Torque | 1/3 of full torque | Full torque |

| Complexity | Moderate (3 contactors, timer) | Simple (1 contactor, relay) |

| Cost | Higher | Lower |

| Suitable Motor Rating | Above 5 HP | Up to 5 HP |

| Transition | Automatic (timed) | None |

| Power Quality | Better (low voltage dip) | May cause voltage drop |

14. Maintenance and Troubleshooting

Regular Maintenance Steps:

- Check contactor contacts for pitting or carbon deposits.

- Verify timer accuracy and reset if transition delay is incorrect.

- Inspect overload relay settings and operation.

- Tighten all terminals to avoid sparking and heat buildup.

- Ensure mechanical interlocking is functional.

Common Issues:

- Motor fails to start: Faulty start button or main contactor coil.

- Motor runs in star mode only: Timer or delta contactor malfunction.

- Frequent tripping: Overload setting too low or supply imbalance.

- Humming sound during transition: Delay misconfiguration or contactor chatter.

15. Advantages Over DOL Starter

The Star-Delta Starter offers a significant advantage over DOL starters by reducing both electrical and mechanical stress during startup. It extends the life of motors, improves power quality, and ensures smoother acceleration—particularly useful for heavy industrial machinery and long-running applications.

16. Conclusion

The Star-Delta Starter remains a cornerstone in industrial motor control due to its balanced design, effectiveness, and simplicity. By intelligently shifting the motor from a star connection (reduced voltage) to a delta connection (full voltage), it ensures smooth acceleration and protects the electrical network from inrush currents.

While modern electronic soft starters and variable frequency drives (VFDs) offer enhanced control, the Star-Delta Starter continues to be a trusted, economical solution in industries worldwide. It bridges the gap between the simplicity of DOL starters and the sophistication of advanced motor control systems, making it an essential part of every electrical engineer’s practical knowledge.

Q1. Why does the Star Delta Starter first connect the motor in a star configuration and then shift to delta?

The motor is first connected in a star configuration to reduce the voltage applied to each winding, limiting the starting current and torque. Once the motor attains about 80% of its rated speed, it is switched to delta configuration to supply full line voltage for normal operation. This dual-step process ensures smooth acceleration and prevents electrical stress.

Q2. What role does the timer relay play in a Star Delta Starter?

The timer relay controls the duration of the star connection and automatically initiates the transition to delta mode after a preset delay. It ensures that the motor shifts from low-voltage to full-voltage operation without manual intervention or electrical overlap between star and delta contactors.

Q3. Why are three contactors used in a Star Delta Starter instead of one?

Three contactors — main, star, and delta — are used to manage the sequential connection of the motor. The main contactor connects power to the circuit, the star contactor forms the star configuration during startup, and the delta contactor reconfigures the windings for full-load running. This arrangement allows safe and automatic switching between modes.

Q4. What happens if the star and delta contactors close at the same time?

If both contactors close simultaneously, it would create a direct short circuit across the supply lines, causing severe damage to the motor and contactors. To prevent this, the circuit uses electrical and mechanical interlocking, ensuring only one contactor operates at a time.

Q5. How is interlocking achieved in a Star Delta Starter control circuit

Interlocking is achieved both electrically and mechanically. Electrically, auxiliary normally closed (NC) contacts prevent the delta contactor from energizing while the star contactor is active. Mechanically, physical locks between contactors ensure they cannot close together, even in case of coil failure.

Q6. What is the effect of the reduced voltage in the star connection on current and torque?

When connected in star, each winding receives only 1/√3 (≈58%) of the line voltage. As a result, the starting current becomes one-third of the DOL starting current, and the starting torque also reduces to one-third of the full-load torque. This ensures a softer start, especially for large motors.

Q7. Why is the Star Delta Starter unsuitable for small motors?

Small motors (below 5 HP) do not draw excessively high starting currents, so the added complexity and cost of a Star Delta Starter are unnecessary. For such motors, a DOL Starter provides a simpler and more economical solution.

Q8. What kind of problems occur during the star-to-delta transition?

During transition, a brief disconnection occurs between star and delta contactors. If the motor speed or voltage phases are not synchronized, a sudden current spike or torque jerk may occur, causing mechanical vibrations or voltage dips in the network.

Q9. What parameters determine the timer setting in a Star Delta Starter?

The timer setting depends on the motor rating, load inertia, and supply voltage. Typically, it ranges between 5 to 10 seconds—enough time for the motor to reach 80% of its rated speed before switching to delta mode. Incorrect timing may result in current surges or incomplete acceleration.

Q10. What are the safety devices used in a Star Delta Starter circuit?

Key safety devices include the MCB or fuse for short-circuit protection, overload relay for current monitoring, and interlocks for ensuring safe switching. These components collectively protect the motor and operator from electrical hazards.