on this page, we will go through the following

What is a vernier caliper?

A vernier caliper is a precise measuring instrument used to measure the internal, external, and depth dimensions of objects with high accuracy. It features a main scale and a vernier scale, which together provide fine readings up to 0.1 mm or 0.02 mm. Widely used in science, engineering, and manufacturing, it ensures reliable dimensional measurements.

Vernieir caliper free PDF

Why Engineers must learn how to use vernier caliper:

Engineers must learn to use a vernier to achieve precise and accurate measurements of components, parts, and assemblies. It enables measurement of internal, external, and depth dimensions, ensuring designs meet specifications. Mastering this tool enhances technical skills, quality control, and problem-solving, which are vital in engineering projects.

If you want to become a QA QC Engineer then learning vernier caliper is must for you

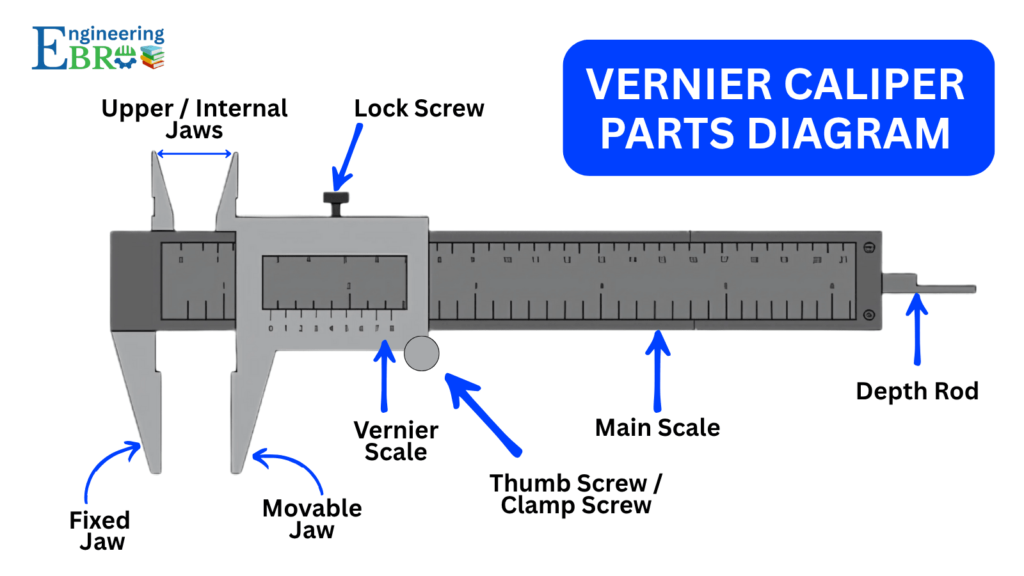

Vernier caliper diagram with parts

8 Main Parts of Vernier caliper with diagram

- Main Scale – Provides the primary measurement in millimeters or inches.

- Vernier Scale – Slides along the main scale for precise readings.

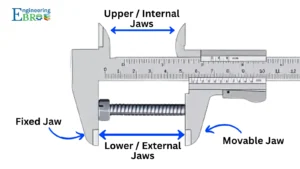

- Fixed Jaw – Stationary jaw attached to the main scale.

- Movable Jaw – Slides to hold the object firmly.

- Upper Jaws – Used for measuring internal dimensions.

- Lower Jaws – Used for measuring external dimensions.

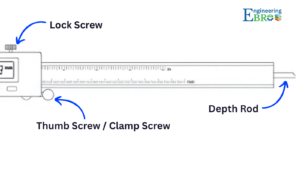

- Depth Rod – Measures the depth of holes or slots.

- Thumb Screw/Clamp Screw – Helps in fine adjustment and locking the scale

Before we proceed on how to use a vernier lets understand what is zero error and how to correct it, this is a crucial step to get correct reading

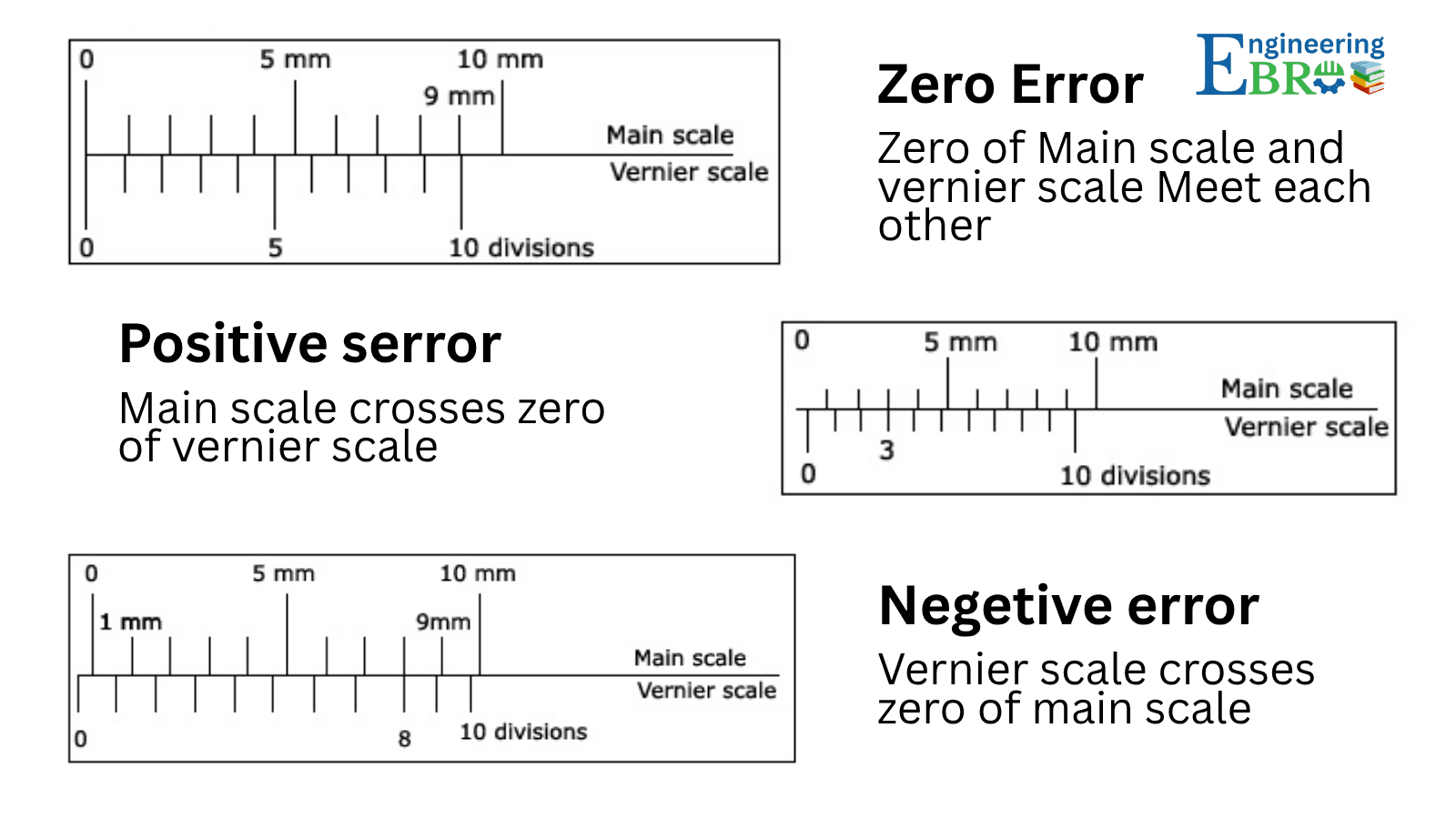

What is Zero Error?

Zero error is the error that occurs when the jaws are fully closed but the zero of the main scale and the zero of the vernier scale do not align. It can be positive zero error (vernier zero ahead of main scale zero) or negative zero error (vernier zero behind). This error must be added or subtracted from the final measurement to get accurate results.

How to Correct Zero Error in Vernier Caliper

To get accurate results, the zero error must be adjusted:

- Positive zero error: Subtract it from the observed reading.

- Negative zero error: Add it to the observed reading.

Formula: Correct Reading = Observed Reading ± Zero Error

Example:

If the observed reading is 25.36 mm and the zero error is +0.02 mm,

Correct Reading = 25.36 – 0.02 = 25.34 mm.

If zero error is –0.02 mm,

Correct Reading = 25.36 + 0.02 = 25.38 mm.

How to use a vernier caliper — step-by-step

Following are the standard steps you should follow to use a vernier caliper

Total time for the process 1 minute

1. Clean & inspect

Wipe the jaws and sliding surfaces; ensure smooth movement.

2. Zero check

Close jaws and confirm main and vernier zeros align; note any zero error.

3. External measure

Place object between lower jaws and slide the movable jaw until it lightly contacts

4. Internal measure

Insert upper jaws into the hole and expand until both faces touch.

5. Depth measure

Insert the depth rod into the hole/slot until the caliper base rests flat.

6. Lock (optional)

Tighten the clamp screw to hold the jaws without over-tightening.

7. Read main scale

Record the value immediately left of the vernier zero (whole mm/in).

8. Read vernier

Find the vernier division that aligns with a main-scale line; multiply that division number by the caliper’s least count (e.g., 0.02 mm).

9. Finish

Release, clean, and store the caliper; repeat measurements if needed for accuracy

Supply:

- Cleaning towel,

- Gloves,

- Bench vice,

Tools:

- Vernier caliper

Materials: Work piece

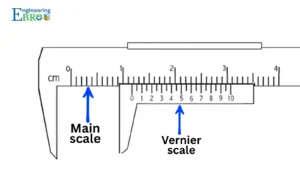

How to read vernier caliper?

- Close and check zero: Ensure the zero of the main and vernier scales align; note any zero error.

- Place the object: Fix it between jaws (external), upper jaws (internal), or depth rod (depth).

- Read the main scale: Record the reading just before the zero of the vernier scale.

- Read the vernier scale: Find the vernier division that exactly coincides with any main scale line.

- Calculate final reading:

- Measurement=Main Scale Reading + (Vernier Division×Least Count)±Zero Error

- Example:

- Main Scale Reading = 12.0 mm

- Vernier Division = 6

- Least Count = 0.02 mm

- Final Reading = 12.0 + (6 × 0.02) = 12.12 mm

- Measurement=Main Scale Reading + (Vernier Division×Least Count)±Zero Error

Example Problems on various measurements using vernier

1. External Measurement

- Problem: Measure the diameter of a rod.

- Observed reading: Main scale = 24 mm, Vernier scale = 7 divisions, Least count = 0.02 mm.

- Solution: Measurement = 24 + (7 × 0.02) = 24.14 mm

2. Internal Measurement

- Problem: Measure the diameter of a hole.

- Observed reading: Main scale = 12 mm, Vernier scale = 3 divisions, Least count = 0.02 mm.

- Solution: Measurement = 12 + (3 × 0.02) = 12.06 mm

3. Depth Measurement

- Problem: Measure the depth of a cylindrical groove.

- Observed reading: Main scale = 15 mm, Vernier scale = 5 divisions, Least count = 0.02 mm.

- Solution: Depth = 15 + (5 × 0.02) = 15.10 mm

4. Measurement with Zero Error

- Problem: External measurement of a rod with positive zero error of 0.02 mm. Observed reading = 18 mm (main) + 4 divisions (vernier), LC = 0.02 mm.

- Solution: Reading = 18 + (4 × 0.02) – 0.02 = 18.06 mm

What is the Least count of Analog vernier caliper

The least count of an analog vernier caliper is 0.02 mm (20 microns) in most standard models. It represents the smallest measurement that can be accurately read using the instrument. Some vernier calipers may have a least count of 0.05 mm, depending on the design and manufacturer.

What is the formula for Least count of vernier?

The least count (LC) of a vernier caliper is calculated using the formula:

Least Count (LC) = (MSD) − (VSD)

MSD = Value of One Main Scale Division

VSD = Value of One Vernier Scale Division

In most standard vernier calipers, one MSD = 1 mm and 10 VSD = 9 mm,

so LC = 1 mm – 0.9 mm = 0.1 mm or further refined to 0.02 mm in precise instruments.

Uses of Vernier Caliper in 2025

- Engineering & Manufacturing: Used to measure external, internal, and depth dimensions of components in automotive, aerospace, and metalworking industries, ensuring precise tolerances and quality control.

- Education & Laboratories: Essential in physics and engineering labs for teaching dimensional analysis and conducting accurate experiments.

- Medical & Dental Fields: Measures anatomical structures, implants, and prosthetics with sub-millimeter accuracy.

- Woodworking & Carpentry: Helps in measuring wood thickness, dowels, and hole depths for precise cuts and joinery.

- Research & Development: Used in advanced fields like photonics for miniaturized spectrometer development and high-resolution spectral analysis.

If you want to select the right caliper for your needs, read this comprehensive guide. It explains how to choose a verniercaliper, as a begineer i too followed this guide in the beginning

Frequently Asked Questions

What is the difference between a vernier caliper and a micrometer?

A vernier caliper measures internal, external, and depth dimensions with moderate precision, while a micrometer provides higher accuracy for external dimensions but cannot measure depth or internal diameters easily.

How accurate is a vernier caliper?

Standard analog vernier calipers have an accuracy of 0.02 mm to 0.05 mm, depending on the least count and quality of the instrument.

Can vernier calipers measure very small or large objects?

Yes, they can measure objects from a few millimeters up to 300 mm or more, depending on the caliper size.

How do I avoid parallax error when reading a vernier caliper?

Always view the scale straight-on at eye level so the main scale and vernier scale align correctly, avoiding misreading.

How often should a vernier caliper be calibrated?

Professional usage requires calibration every 6–12 months to maintain accuracy, or sooner if the caliper is heavily used or dropped.

Can vernier calipers measure irregular-shaped objects?

Yes, but for irregular objects, careful positioning and multiple measurements are needed to ensure accuracy.

What is zero error and how is it corrected?

Zero error occurs when the jaws are closed but the zeros do not align. Positive error: subtract from reading; Negative error: add to reading

Are vernier calipers still used in industries in 2025?

Yes, they are widely used in engineering, manufacturing, medical, educational, and research applications for precise measurements.

Can vernier calipers measure both inches and millimeters?

Yes, many calipers have dual scales for metric (mm) and imperial (inch) readings, making them versatile

How do I maintain a vernier for long-term accuracy?

Keep it clean, free from dust and oil, avoid drops, store in a protective case, and check zero before each use.