What is a Chamfered Edge

The chamfered edge is defined as the edges/corners of the workpiece that have been cut / Beveled instead of leaving it with sharp edges and corners

Chamfered edges are made for Several reasons

-

To improve the appearance of the workpiece

-

To improve the functionality of the workpiece

-

To make the workpiece safe to work (Reduce the chances of Injury)

-

To make the assembly easy

Most importantly it is done to reduce the stress concentration on the edges

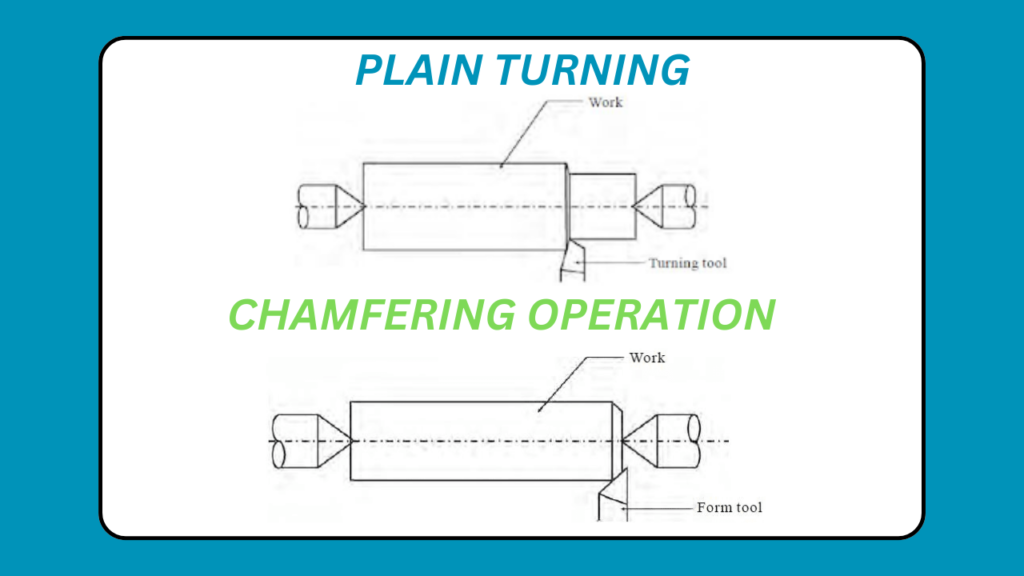

How to create Chamfered Edge?

Chamfered edges can be made using hand tools that are commonly used in carpentry shops such as hand grinding tools, sandpapers, Flat files and more, apart from these tools there are specialized tools such as chamfering mills and chamfering machines.

The angle and depth of the chamfer can be customized based on the specific requirements of the project and can range from a slight bevel to a deep angled edge.

| chamfered edge |

How to create Chamfered Edge on a blender?

Applications

Chamfered edges are used in various domains of Manufacturing physical products, few manufacturing processes are as follows

1 Carpentry

2 Metal working

3 Machining

Advantages

These edges offer several advantages in various applications.

Improved Safety:

Chamfered edges are often used in place of sharp corners to enhance safety. By rounding off the edges, they reduce the risk of injuries caused by accidental bumps or collisions. Chamfered edges are commonly found on furniture, countertops, and children’s toys to minimize the chances of sharp impacts.

Enhanced Durability:

The chamfered-edge design helps to distribute stress and impact forces more evenly along the edge, which can improve the overall durability of the object. When an object with a chamfered edge experiences a sudden impact, the rounded profile helps to reduce the concentration of stress at a single point, making it less prone to cracking or chipping.

Aesthetic Appeal:

Chamfered edges can add an element of style and elegance to various objects and architectural elements. The beveled profile adds a subtle visual interest, breaking up sharp angles and creating a more refined appearance. This aesthetic advantage is often utilized in the design of furniture, decorative moldings, and even electronic devices.

Easy Assembly:

Chamfered edges can facilitate the assembly of components by providing a guide for alignment. When two pieces with chamfered edges are brought together, they can easily slide into position, ensuring a precise fit. This advantage is particularly useful in the woodworking, metalworking, and construction industries.

Smoother Transitions:

Chamfered-edges help to create smoother transitions between different surfaces or materials. When two surfaces meet at an angle, a chamfered edge can provide a gradual slope, eliminating any sudden or abrupt changes. This is particularly beneficial in applications where materials need to be joined, such as in carpentry or masonry work.

Easier Maintenance:

Chamfered-edges can be easier to clean and maintain compared to sharp corners. Sharp edges tend to accumulate dirt, debris, and moisture, which can be challenging to remove. In contrast, chamfered edges are less prone to trapping particles, allowing for easier cleaning and reducing the risk of bacterial growth.

Overall, chamfered-edges offer a combination of functional and aesthetic benefits, ranging from improved safety and durability to enhanced visual appeal and ease of assembly.

when you should not create a chamfered edge?

While chamfered-edges have various advantages, there are certain situations where creating a chamfered edge may not be suitable. Here are a few scenarios where a chamfered edge may not be desirable:

1. Structural Integrity:

In some cases, maintaining sharp corners or edges is essential for maintaining the structural integrity of an object. Sharp edges can provide added strength and stability, especially in load-bearing structures or components where rigidity is critical. Chamfering these edges may compromise their strength or stability.

2. Design Intent:

In certain design styles or aesthetics, sharp corners or edges may be intentionally desired for visual impact or to convey a specific message or theme. Chamfering these edges would alter the intended design concept and may not align with the overall artistic vision.

3. Functional Requirements:

In certain applications, such as gripping surfaces or mechanical interfaces, sharp edges may be necessary to ensure proper functionality. For instance, tools, handles, or machine parts that require a firm grip or precise contact may not benefit from chamfered edges, as they could reduce the necessary friction or contact area.

4. Material Limitations:

Some materials, especially brittle or fragile ones, may not be suitable for chamfered edges. Chamfering such edges can weaken the material or increase the risk of cracking or breakage. It’s important to consider the material properties and limitations before deciding to create chamfered edges.

5. Cost and Time Constraints:

Chamfered-edges may require additional manufacturing processes or specialized tools, which can increase production costs or time. In situations where cost or time is a significant constraint, it may be more practical to avoid chamfering and opt for simpler edge treatments.

Ultimately, the decision to create chamfered-edges or maintain sharp corners depends on the specific requirements, functional considerations, design intent, and material properties of the object or structure in question.

For example, chamfered-edges of two metal parts that need to be welded together can help create a stronger and more secure joint by providing more surface area for the weld to adhere to.

Overall, a chamfered-edge of a workpiece can help improve the appearance, functionality, and safety of the workpiece, and can be easily achieved using a variety of manual or automated chamfering tools.

Checkout our home page for more informative content, Make sure to follow us on facebook