Introduction

In industrial machinery, connecting two rotating shafts while allowing for minor misalignments is essential for smooth operation. One of the most reliable solutions for this is the Oldham coupling. Known for its simplicity, precision, and flexibility, this coupling is widely used in industries ranging from pharmaceuticals to pumps, conveyors, and robotics.

This article provides a detailed overview of Oldham coupling, including its definition, parts, mechanism, assembly, types, applications, and differences from other couplings like jaw coupling.

We will explore following:

ALSO READ:

What is Coupling? Types, Functions & Global Leaders 2025

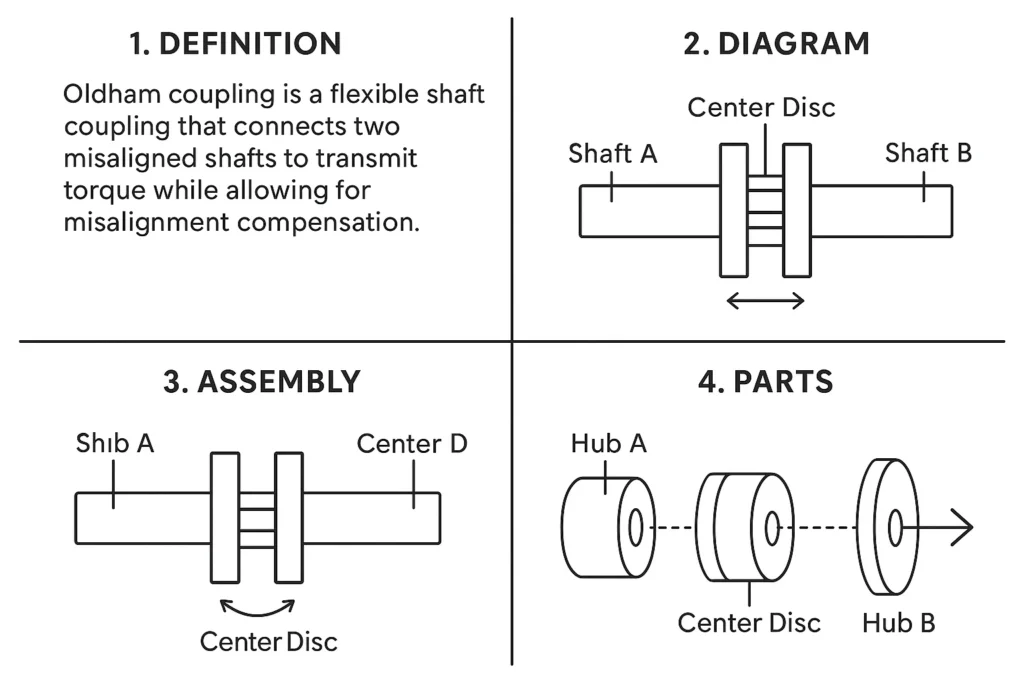

1. Definition of Oldham Coupling

An Oldham coupling is a type of flexible shaft coupling used to connect two parallel shafts that are slightly misaligned. Its primary function is to transmit torque between the shafts while compensating for misalignment. This makes it ideal for applications where high precision is required or where shafts cannot be perfectly aligned due to installation constraints.

Unlike rigid couplings, Oldham couplings can accommodate radial, axial, and angular misalignments, making them versatile for a wide range of machinery.

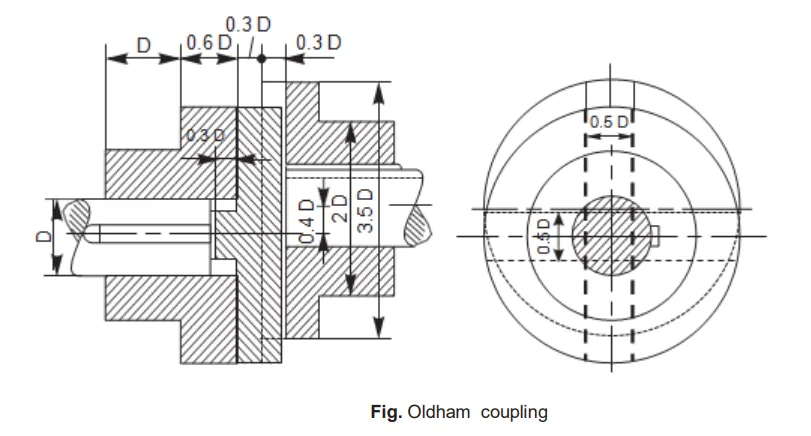

2. Parts of Oldham Coupling

An Oldham coupling consists of three main components:

- Hubs (2) – Each hub is attached to one of the shafts. The hubs are usually made of steel or aluminum and have a slot cut on one side.

- Center Disc – A flat disc with grooves on opposite faces. These grooves are oriented at 90° to each other to allow sliding motion between the hubs. The center disc is usually made of nylon, acetal, or other polymers for smooth sliding and minimal wear.

- Keys/Slots – These help in torque transmission by locking the disc with the hub grooves, ensuring the rotation of one shaft drives the other.

3. Mechanism of Oldham Coupling

The functioning of an Oldham coupling relies on the sliding action of the center disc. Here’s how it works:

- Torque Transmission: When Shaft A rotates, its hub pushes the center disc via the groove.

- Sliding Motion: The center disc slides in the groove of Hub B, transmitting torque to Shaft B.

- Misalignment Compensation: This sliding allows the coupling to absorb radial misalignment between the shafts while still transmitting torque efficiently.

Key Advantage: Smooth torque transmission without putting excessive stress on shafts or bearings, which is crucial in precision machinery.

4. Types of Oldham Coupling

Oldham couplings are categorized based on size, precision, and application:

- Standard Oldham Coupling:

- General-purpose coupling for moderate torque applications.

- Common in conveyor systems and low-speed machinery.

- Precision Oldham Coupling:

- High-accuracy coupling designed for CNC machines, robotics, and medical devices.

- Minimizes backlash and vibration, providing smooth motion.

- Miniature Oldham Coupling:

- Compact design for small motors and lightweight applications.

- Used in laboratory instruments, small pumps, and servo motors.

5. Assembly Drawing of oldham coupling

The assembly drawing is straightforward:

- Mount Hub A on Shaft A and secure it with screws or keys.

- Mount Hub B on Shaft B similarly.

- Insert the Center Disc between the two hubs. The grooves on the disc must align with the hub slots.

- Check Alignment to ensure the disc can slide freely without excessive gaps.

- Rotation Test: Rotate Shaft A slowly to ensure smooth motion of the disc and proper torque transmission.

Diagram suggestion: A CAD-style drawing showing hub attachment, center disc positioning, and direction of rotation.

6. Applications in Industries

Oldham couplings are widely used across industries where precision, smooth motion, and misalignment compensation are essential.

a) Pharmaceutical Industry

- Equipment: Tablet presses, mixers, capsule filling machines, conveyors.

- Why Oldham Coupling? Smooth torque transmission prevents vibration, which is critical for accurate dosing and uniform mixing. Radial misalignment in conveyor shafts is compensated, reducing downtime.

b) Pumps and Fluid Handling Industry

- Equipment: Centrifugal pumps, gear pumps, dosing pumps.

- Why Oldham Coupling? Compensates for misalignment between motor and pump shafts, protecting bearings and pump seals from excessive wear. Its flexibility ensures continuous operation in pumping and fluid transfer systems.

c) CNC and Robotics

- Equipment: CNC routers, 3D printers, robotic arms.

- Why Oldham Coupling? Precision Oldham couplings reduce backlash and vibration, ensuring accurate motion control. Radial misalignment in small motors or actuators is easily accommodated.

d) Packaging Industry

- Equipment: Conveyor belts, labeling machines, filling machines.

- Why Oldham Coupling? Ensures smooth torque transfer even when shafts are slightly misaligned, reducing product damage and operational stoppages.

e) General Manufacturing

- Equipment: Motors driving gearboxes, conveyor systems, and machine tools.

- Why Oldham Coupling? Easy to maintain, reduces wear on connected shafts, and improves equipment lifespan.

7. Uses / Advantages

- Misalignment Compensation: Handles radial, axial, and angular misalignment efficiently.

- Vibration Reduction: Smooth sliding action reduces vibration on connected shafts.

- Low Maintenance: Simple construction with easily replaceable center disc.

- Versatility: Can be used in high-precision machines and moderate-speed industrial equipment.

- Cost-Effective: Affordable solution compared to complex flexible couplings.

8. Difference Between Oldham and Jaw Coupling

| Feature | Oldham Coupling | Jaw Coupling |

|---|---|---|

| Misalignment Handling | Radial, angular, axial | Primarily angular & axial |

| Construction | Hub + center disc (sliding action) | Hub + elastomeric spider |

| Applications | CNC machines, conveyors, pumps | Motors, pumps, general machinery |

| Shock Absorption | Low | High (due to elastomer) |

| Torque Transmission | Moderate | Moderate to high |

| Maintenance | Replaceable center disc | Elastomeric element may wear over time |

Key Takeaway: Oldham couplings are preferred in precision-driven applications, while jaw couplings are better for shock-absorbing, high-torque situations.

9. Material Considerations

- Hubs: Steel, aluminum, or brass depending on torque and weight requirements.

- Center Disc: Nylon, acetal, or reinforced plastic for low friction and wear resistance.

- Coatings: Some high-speed applications use lubricated or coated discs to minimize heat and wear.

10. Maintenance Tips

- Regular Inspection: Check the center disc for wear, cracks, or deformation.

- Proper Alignment: Ensure hubs are mounted correctly to minimize disc sliding wear.

- Lubrication: Some designs may require light lubrication for high-speed applications.

- Replacement: The center disc is replaceable without removing the hubs, reducing downtime.

11. Choosing the Right Oldham Coupling

When selecting an Oldham coupling for industrial applications, consider:

- Torque Rating: Ensure the coupling can handle the transmitted load.

- Shaft Diameter: Hubs should match the shaft sizes.

- Misalignment Tolerance: Check maximum radial, axial, and angular misalignment.

- Speed: Higher RPM requires precision materials and sometimes lubrication.

- Environmental Conditions: Temperature, chemical exposure, or humidity may affect material choice.

12. Additional User Information

- Center Disc Replacement: Quick and cost-effective, extending coupling life.

- Custom Designs: Available for non-standard shaft distances or high-torque applications.

- Compact Design: Ideal for machines with limited space.

- Precision Motion: Reduces backlash in CNC machines and robotic systems.

Conclusion

Oldham coupling is a versatile, reliable, and efficient solution for connecting misaligned shafts in industrial applications. Its unique sliding center disc allows torque transmission while compensating for radial, angular, and axial misalignments. With applications in pharmaceutical machinery, pumps, robotics, CNC machines, and conveyors, it is an essential component in modern industrial equipment. Choosing the right Oldham coupling ensures smooth operation, reduces wear on connected components, and enhances overall equipment longevity.