Quality Assurance Engineer?

A Quality Assurance Engineer (QA) ensures that products, processes, and services meet defined quality standards across various industries. Their role is to prevent defects, improve efficiency, and ensure compliance with regulations

Table of Contents

What are the roles and responsibilities of a quality assurance engineer?

1. Establishing Quality Standards

✅ Define quality criteria based on company policies, customer expectations, and industry regulations.

✅ Develop quality control processes for inspections and testing.

2. Creating & Implementing Testing Procedures

✅ Design test plans, cases, and checklists for products or systems.

✅ Choose manual or automated testing methods depending on the industry.

3. Conducting Inspections & Tests

✅ Perform visual inspections, functional tests, and stress tests on products.

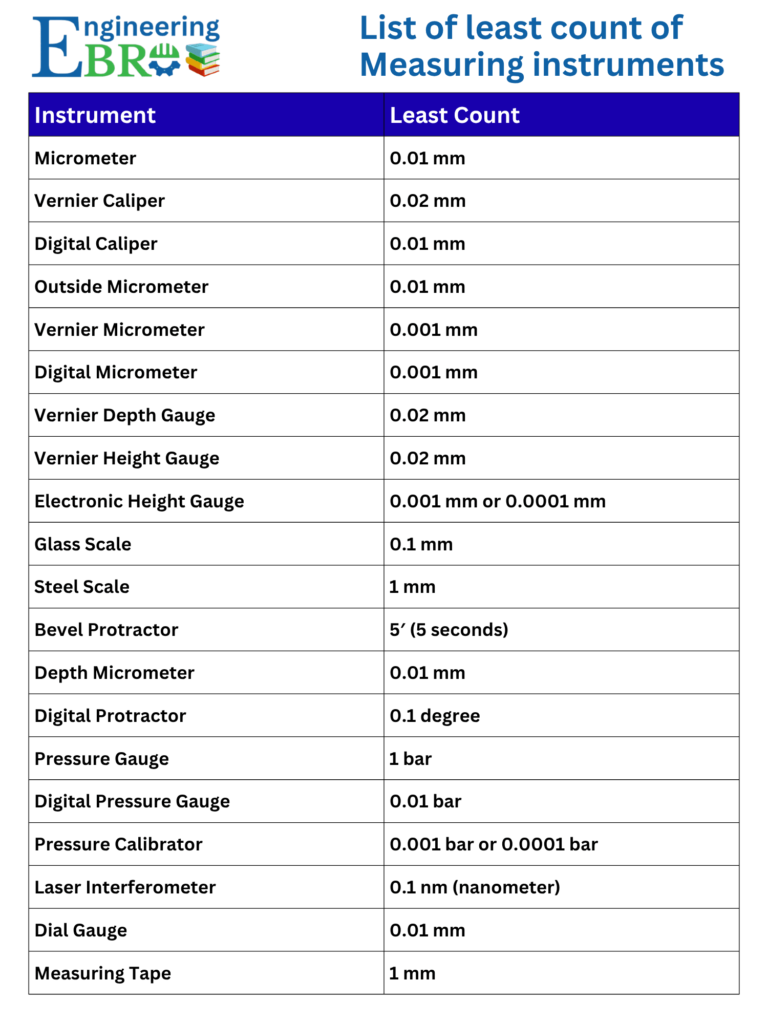

✅ Use measurement tools, software simulators, and lab equipment to verify quality.

4. Identifying & Documenting Defects

✅ Detect and analyze errors, defects, or non-conformities in the product.

✅ Maintain detailed reports with test results and failure reasons.

✅ Use bug tracking systems like JIRA (software) or defect logs (manufacturing).

5. Root Cause Analysis & Process Improvement

✅ Conduct root cause analysis (RCA) using methods like Fishbone diagrams, 5 Whys, or Six Sigma tools.

✅ Suggest corrective and preventive actions (CAPA) to eliminate defects and improve quality.

6. Ensuring Compliance with Industry Standards

✅ Follow national and international quality standards such as ISO 9001, ASME, ASTM, API, FDA, GMP, HACCP, ISTQB, ISO 27001.

✅ Conduct internal audits to ensure compliance.

7. Collaborating with Different Teams

✅ Work with design, production, and sales teams to improve quality at every stage.

✅ Provide feedback to engineers, developers, or suppliers for product enhancements.

8. Supplier & Vendor Quality Management

✅ Conduct supplier audits to ensure they meet quality requirements.

✅ Inspect raw materials and approve/reject shipments based on quality tests.

9. Documentation & Reporting

✅ Maintain records of test results, audits, and quality certifications.

✅ Prepare compliance reports for stakeholders or regulatory bodies.

10. Training & Continuous Improvement

✅ Conduct quality awareness training for employees.

✅ Promote a culture of continuous improvement (Kaizen, Lean, Six Sigma).

List of types of companies where you will find the role of quality assurance engineer

1. Manufacturing Companies

- Automotive (Toyota, Ford, Tata Motors)

- Electronics (Samsung, Sony, Intel)

- Heavy Machinery (Caterpillar, Komatsu)

2. Mechanical & Industrial Equipment Companies

- Pump Manufacturing (Grundfos, KSB, Kirloskar)

- HVAC & Refrigeration (Carrier, Daikin)

- Industrial Tools & Equipment (Bosch, Makita)

3. Aerospace & Defense Companies

- Aircraft Manufacturing (Boeing, Airbus)

- Space Technology (SpaceX, ISRO, NASA)

- Defense Equipment (Lockheed Martin, Raytheon)

4. Oil & Gas Companies

- Oil Refineries (ExxonMobil, Shell, BP)

- Pipeline & Storage (TransCanada, Indian Oil)

- Drilling Equipment (Halliburton, Schlumberger)

5. Pharmaceutical & Healthcare Companies

- Drug Manufacturing (Pfizer, Sun Pharma, Novartis)

- Medical Devices (Medtronic, Johnson & Johnson)

- Biotechnology (Biocon, Genentech)

6. Food & Beverage Companies

- Packaged Foods (Nestlé, PepsiCo, Britannia)

- Dairy & Beverages (Amul, Coca-Cola)

- Fast Food Chains (McDonald’s, KFC)

7. Construction & Civil Engineering Companies

- Infrastructure & Real Estate (L&T, Bechtel)

- Cement & Building Materials (UltraTech, ACC Cement)

- Structural Engineering (Arup, WSP)

8. Software & IT Companies

- Software Development (Microsoft, Google, TCS)

- Mobile App Development (Apple, Adobe)

- Cybersecurity & Cloud (IBM, Oracle)

9. Consumer Goods & Electronics Companies

- Smartphones & Gadgets (Apple, Xiaomi, Samsung)

- Home Appliances (LG, Whirlpool)

- Wearable Tech (Fitbit, Garmin)

10. Textile & Apparel Companies

- Fashion Brands (Nike, Adidas, H&M)

- Fabric Manufacturing (Raymond, Arvind Mills)

- Footwear Companies (Bata, Puma)

11. Renewable Energy & Power Companies

- Solar Panel Manufacturing (Tata Power Solar, First Solar)

- Wind Turbine Companies (Siemens Gamesa, GE Renewable)

- Power Generation (NTPC, Adani Power)

12. Logistics & Supply Chain Companies

- Shipping & Freight (Maersk, FedEx, DHL)

- Warehousing & Distribution (Amazon, Walmart)

Common Skills Required for Quality Assurance Engineers Across Industries

✔ Attention to detail – Identify defects and inconsistencies.

✔ Knowledge of quality standards – ISO, ASTM, API, Six Sigma, etc.

✔ Testing techniques – Manual inspection, automation tools, lab tests.

✔ Problem-solving skills – Root cause analysis & process improvement.

✔ Documentation & reporting – Keeping track of test results & compliance.

Every industry has a Quality Assurance Engineer, but their tools, techniques, and standards differ.